| Posted: Feb 14, 2018 |

Micromotors made easy

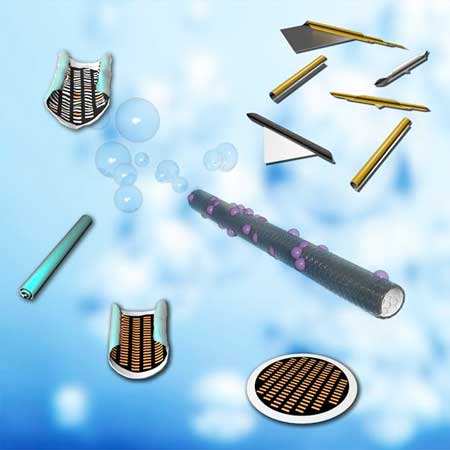

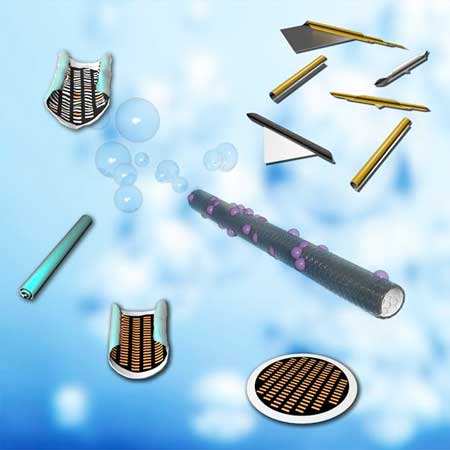

(Nanowerk News) Researchers of the ICN2 Bioelectronics and Biosensors Group led by Prof. Arben Merkoçi have devised a simple manufacturing method for versatile graphene oxide-based micromotors. Requiring no specialist equipment, it can be used to produce a range of micromotors that can be further tuned for different purposes. Luis Baptista-Pires explains the process in the paper published in Small ("Architecting Graphene Oxide Rolled-up Micromotors: A Simple Paper-Based Manufacturing Technology").

|

|

|

Perhaps the easiest way to introduce the concept of a micromotor is to take the familiar idea of a motor and strip it down to its bare essentials: requires fuel, does work. Acting at the microscale, they are materials or structures that can be designed such that, when released into an aqueous environment, they carry out a range of tasks. They rotate, they shuttle, they deliver, they collect… all manner of actions that allow them to interact with living cells, chemical pollutants and even circuitry at a scale that we cannot.

|

|

The motors developed by researchers of the ICN2 Bioelectronics and Biosensors Group, led by ICREA Prof. Arben Merkoçi, have been used in test conditions to remove oil droplets from water. Comprising tiny rolled sheets of graphene oxide, these structures can zip around easily through both oil and water, picking up any oil particles they encounter and transporting them as cargo for later release.

|

|

But the real breakthrough, and the focus of the paper published in Small with lead author Luis Baptista-Pires, is the innovative, almost playfully simple production method used to build these micromotors. Adapting an existing in-house technology, a graphene oxide solution is poured onto a wax-printed paper membrane. This membrane acts as a kind of mould which, when wetted briefly in water and then hand-shaken (yes, hand-shaken) from side to side in ethanol, sets and releases multiple self-rolled graphene oxide tubes – the basic building block of our micromotors.

|

Just add fuel

|

|

As part of the same manufacturing process, these roll-up micromotors can be lined with platinum. When the motors are released into the environment where they will perform their task, a small quantity of hydrogen peroxide is also released. This chemical compound reacts with the platinum lining, creating bubbles and, with it, forward motion. Alternatively the motors can be lined with magnetic particles, allowing external steering using magnets.

|

|

Importantly, the manufacturing process developed at the ICN2 is vastly cheaper and simpler than existing methods to produce micromotors, and requires no special equipment. It also offers significant control over the direction in which the graphene oxide rolls up – whether lengthways, sideways or diagonally. Since differently scrolled micromotors exhibit different behaviours as they move through the liquid, this too is important to the viability of micromotor technologies on a large scale: to be useful, we need to be able to produce batches of motors able to perform the same task.

|

|

Besides experimenting with different roll-up directions, the team also tried varying the thicknesses of the scrolls and the reduction levels of the solution used to make them (that is, decreasing the proportion of oxygen in the oxide). This resulted in motors with different internal structures and surface characteristics, with the different solutions setting differently and/or scrolling more or less tightly upon release from the membrane. All of these variables open up myriad ways of tuning the micromotors for specific tasks.

|

|

Micro- and nanomotors represent an emerging field of research that is already finding potential applications, from medical interventions and health diagnostics to energy storage and environmental monitoring. However, some major hurdles still remain before these can be fully realised. For instance, the fuels these motors typically run on are not wholly biocompatible. In the case of our roll-up variety, this rules out their immediate scaling up for cleaning oil spills until a more environmentally friendly compound can be found.

|

|

That said, the efforts of this ICN2 group do bring us one step closer. Previously, manufacturing had also been a hurdle. But the simple, inexpensive method presented in this paper paves the way for the mass production of purpose-designed micromotors in a not-so-distant future.

|