| Posted: Feb 15, 2018 |

Gel uses nanoparticles for on-demand control of droplet shapes

(Nanowerk News) Until now, producing liquids that can be shaped and reshaped on demand hasn’t been possible. Scientists discovered a simple way to form stabilized droplets in a variety of structures. Tightly packed nanoparticle-polymer assemblies at droplet surfaces were squeezed into desired shapes assemblies with an electric field. This new approach is a simple route to form droplets of one liquid phase in another liquid. This could lead to the continuous production of discrete, responsive, and reconfigurable all-liquid systems.

|

|

This is a unique platform for printing liquids into structures such as small tubes or special sponge-like gels with desired channel dimensions. This printing can structure, re-organize, and indefinitely lock-in the spatial arrangement of liquids. The result? The printed liquids can create optimized pathways for the flow of mechanical, electrical, or optical energy through a material. Tuning compression at the surface may lead to advanced—even revolutionary—energy storage and catalyst technologies.

|

|

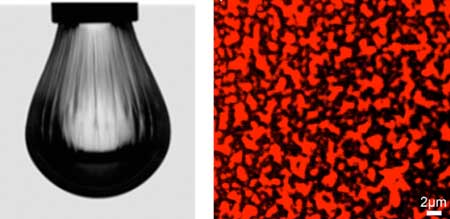

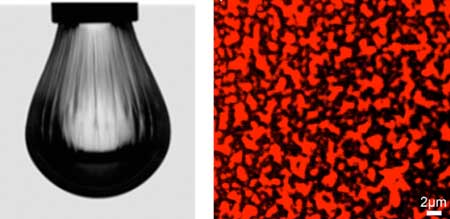

| Paralleling your favorite oil-based salad dressing, combining nanoparticles and a soap-like material (surfactant) goes one step further—tunable channels are stabilized in the mixture. Left: A water droplet with a trapped, a.k.a. jammed, nanoparticle-surfactant assembly at its surface. Withdrawing the “water-liking” phase caused the single layer of assemblies to compress. The visible wrinkles developed immediately, suggesting a “solid-like” nature of the squeezed assemblies. And, the process is reversible. Right: A confocal fluorescence image shows the bicontinuous structure of the nanoparticle-surfactant mixtures. (Image: Lawrence Berkeley National Laboratory)

|

|

Biological cells compartmentalize the functions of proteins and enzymes within organelles and organize into tissues that coordinate to perform work. Trapping, a.k.a. jamming, nanoparticles at water droplet surfaces offers unparalleled routes to similarly compartmentalize human-made matter resulting in the assembly of structured liquids.

|

|

Scientists at Lawrence Berkeley National Laboratory have demonstrated that two liquids that do not mix (called immiscible) can be shaped on demand into stable non-spherical structures. The key is tightly packed nanoparticle surfactants (soap-like materials) at droplet surfaces that are squeezed by an electric field.

|

|

A water droplet containing nanoparticles decorated with negatively charged functional groups was first created. The water droplet was in an oil containing polymers with complementary positively charged groups at one end. This allowed the opposite charges to form assemblies at the water-oil interface. An electric field was applied across the droplet, deforming it into an elongated shape with increased surface area.

|

|

This allowed more assemblies to form at the droplet surface. Upon removal of the electric field, the droplet attempted to revert to a lower surface area shape (sphere). However, the assemblies were compressed and jammed at the interface. This caused the shape of the liquid to be fixed, “arresting” the liquid in an otherwise highly unstable shape.

|

|

Suppressing the instability enables development of a continuous process for forming highly uniform droplets with a wide range of shapes. Moreover, droplet configuration can be controllably changed. Subsequent application of a force such as an electric or magnetic field can cause the droplet to deform. The jammed assemble becomes fluid. This allows its spatial organization to be reconfigured and a new droplet shape to form after removal of the field.

|

|

Using this simple process, two immiscible liquids produced the first torturous, all-liquid structure with interconnected sub-micrometer (narrower than a human hair) channels and a persistent shape. Such “bijels” (bicontinuous jammed emulsion) may have advantages as materials for catalysis and energy storage, but difficulties in producing them and reducing the size of their channel have limited their value to date.

|

|

This nanoparticle-surfactant approach is simpler and led to bijels with tunable channel sizes—even down to ten times lower than currently possible. A wide range of liquid, nanoparticle, and polymer chemistries and concentrations can be used.

|

|

These findings provide valuable guidance for the selection of functionalized nanoparticles and polymers to tune the droplet assembly process to generate structured liquids in a predictable manner.

|

Publications

|

|

A. Toor, B. Helms, and T.P. Russell, “Effect of nanoparticle surfactants on the breakup of free-falling water jets during continuous processing of reconfigurable structured liquid droplets.External link” Nano Letters 17, 3119 (2017). [DOI: 10.1021/acs.nanolett.7b00556]

|

|

C. Huang, J. Forth, W. Wang, K. Hong, G. Smith, B.A. Helms, and T.P. Russell, “Bicontinuous structured liquids with sub-micrometre domains using nanoparticle surfactantsExternal link.” Nature Nanotechnology 12, 1060 (2017). [DOI: 10.1038/nnano.2017.182]

|