| Posted: Mar 05, 2018 |

Modified, 3D-printable alloy shows promise for flexible electronics, soft robots

(Nanowerk News) Researchers in Oregon State University’s College of Engineering have taken a key step toward the rapid manufacture of flexible computer screens and other stretchable electronic devices, including soft robots.

|

|

The advance by a team within the college’s Collaborative Robotics and Intelligent Systems Institute paves the way toward the 3D printing of tall, complicated structures with a highly conductive gallium alloy.

|

|

Researchers put nickel nanoparticles into the liquid metal, galinstan, to thicken it into a paste with a consistency suitable for additive manufacturing.

|

|

“The runny alloy was impossible to layer into tall structures,” said Yigit Mengüc, assistant professor of mechanical engineering and co-corresponding author on the study. “With the paste-like texture, it can be layered while maintaining its capacity to flow, and to stretch inside of rubber tubes. We demonstrated the potential of our discovery by 3D printing a very stretchy two-layered circuit whose layers weave in and out of each other without touching.”

|

|

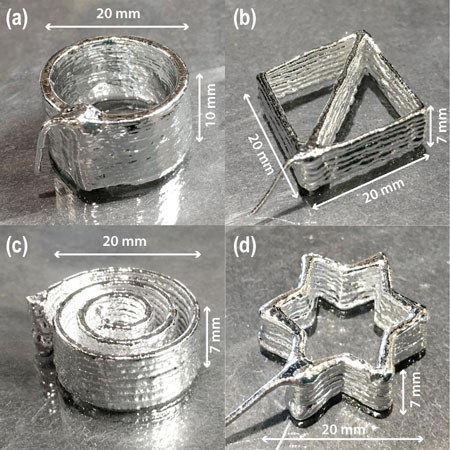

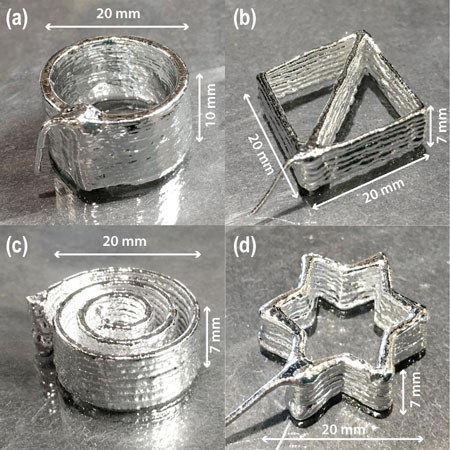

| Sample 3D prints. (Image: Oregon State University)

|

|

Findings were recently published in Advanced Materials Technologies ("Rheological Modification of Liquid Metal for Additive Manufacturing of Stretchable Electronics").

|

|

Gallium alloys are already being used as the conductive material in flexible electronics; the alloys have low toxicity and good conductivity, plus they’re inexpensive and “self-healing” – able to attach back together at break points.

|

|

But prior to the modification developed at OSU, which used sonication – the energy of sound – to mix the nickel particles and the oxidized gallium into the liquid metal, the alloys’ printability was restricted to 2-dimensional.

|

|

For this study, researchers printed structures up to 10 millimeters high and 20 millimeters wide.

|

|

“Liquid metal printing is integral to the flexible electronics field,” said co-author Dogan Yirmibesoglu, a robotics Ph.D. student at OSU. “Additive manufacturing enables fast fabrication of intricate designs and circuitry.”

|

|

The field features a range of products including electrically conductive textiles; bendable displays; sensors for torque, pressure and other types of strain; wearable sensor suits, such as those used in the development of video games; antennae; and biomedical sensors.

|

|

“The future is very bright,” Yirmibesoglu said. “It’s easy to imagine making soft robots that are ready for operation, that will just walk out of the printer.”

|

|

The gallium alloy paste demonstrates several features new to the field of flexible electronics, added co-corresponding author Uranbileg Daalkhaijav, Ph.D. candidate in chemical engineering.

|

|

“It can be made easily and quickly,” Daalkhaijav said. “The structural change is permanent, the electrical properties of the paste are comparable to pure liquid metal, and the paste retains self-healing characteristics.”

|

|

Future work will explore the exact structure of the paste, how the nickel particles are stabilized, and how the structure changes as the paste ages.

|