| Posted: May 17, 2018 |

Functional films made of environmentally friendly clay minerals and dyes

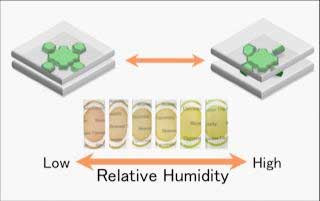

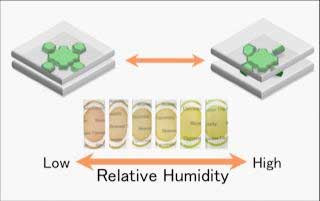

(Nanowerk News) Researchers from Tokyo Metropolitan University and Shimane University have created a transparent hybrid film that combines natural clay minerals and dyes into a material that changes color in response to environmental humidity. The color change does not involve breaking chemical bonds; the team uncovered a novel mechanism that makes the process easily reversible, for long-lasting functionality using environmentally friendly materials. Applications include environmental sensors, and state-of-the-art light amplification in displays.

|

|

| Transparent hybrid film composed of environmentally friendly clay minerals and dyes, that changes color with humidity via a novel mechanism. (Image: Shinsuke Takagi)

|

|

Combining dyes with a wide range of natural minerals like clathrates (clays) and zeolites (porous rock) is a widely applied, promising strategy for creating hybrid materials that can interact with light, or "chromic" materials.

|

|

The physical structure of these materials plays a key role; tiny, nanometer-sized cavities play host to light-sensitive molecules which behave differently from when they are free in solution, with potential applications to light emitting devices, light harvesting (like in solar cells) and novel sensors.

|

|

A team led by Prof Takuya Fujimura from the Department of Physics and Materials Science, Shimane University, and Prof Shinsuke Takagi from the Department of Applied Chemistry, Tokyo Metropolitan University, have created a transparent film made of an environmentally-friendly clay mineral and a dye, magnesium porphyrin, that changes color in response to humidity (Langmuir, "Optical Humidity Sensing Using Transparent Hybrid Film Composed of Cationic Magnesium Porphyrin and Clay Mineral").

|

|

What makes this film special is the mechanism by which it achieves such a striking change. Clays have a layered structure, with nanometer-scale thin spaces in between. The team made a technical breakthrough in getting the dye into these gaps without forming aggregates, to ensure an effective response. The clay layers change their spacing in response to humidity; the confinement of the dye changes.

|

|

More specifically, the electrons surrounding the dye molecule, particularly those involved in how it interacts with light, are made to line up with certain chemical groups in the clay, dramatically changing its color. Note that no chemical bonds are broken or made. This makes the film more compatible with repeated switching, with less degradation of the material.

|

|

The film is not just more durable. Both the clay and dye could be naturally derived materials. That means lower cost, improved safety and enhanced compatibility with the environment. The team hopes to apply the film and new mechanism to sensors and amplification in light emitting devices.

|