| Jul 31, 2018 | |

Better way found to determine the integrity of metals(Nanowerk News) Researchers at the University of Waterloo have found a better way to identify atomic structures, an essential step in improving materials selection in the aviation, construction and automotive industries (Nature Communications, "Insightful classification of crystal structures using deep learning"). |

|

| The findings of the study could result in greater confidence when determining the integrity of metals. | |

|

|

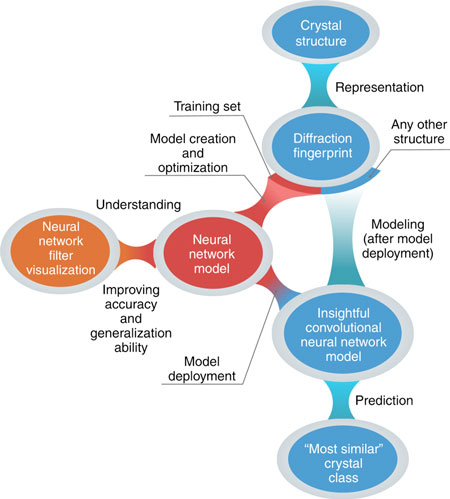

| The model workflow of automatic crystal structure classification. First, every crystal structure is represented by the two-dimensional diffraction fingerprint. Then, a small subset of these structures are used as training set to generate a classification model. In particular, a convolutional neural network is used, and optimized minimizing the training set classification error. However, this is in general not enough to have a sound and generalizable model. Thus, we unfold the neural network internal operations by visualization, and ensure that the model arrives at its classification decision on physically motivated grounds. Finally, a classification model is deployed, and crystal structures can be directly and efficiently classified without any additional model optimization. (© Nature Communications) | |

| Devinder Kumar, a PhD candidate in systems design engineering at Waterloo, collaborated with the Fritz Haber Institute (FHI) in Berlin, to develop a powerful AI model that can accurately detect different atomic structures in metallic materials. The system can find imperfections in the metal that were previously undetectable. | |

| "Anywhere you have metals you want to know the consistency, and that can't be done in current practical scenarios because current methods fail to identify the symmetry in imperfect conditions," said Kumar, who is a member of the Vision and Image Processing Research Group under the supervision of Alexander Wong, a professor at Waterloo and Canada Research Chair in the area of artificial intelligence. | |

| "So, this new method of evaluating metallic material will lead to better material design overall and has the potential to affect all the industries where you need material designing properties." | |

| FHI came up with a new scenario that can artificially create data which relates to the real world. Kumar along with his collaborators was able to use this to generate about 80,000 images of the different kind of defects and displacements to produce a very effective AI model to identify various types of crystal structures in practical scenarios. This data has been released to the public so people can actually learn their own algorithms. | |

| "In theory, all metallic materials have perfect symmetry, and all the items are in the correct place, but in practice because of various reasons such as cheap manufacturing there are defects," Kumar said. "All these current methods fail when they try to match actual ideal structures, most of them fail when there is even one per cent defect." | |

| "We have made an AI-based algorithm or model that can classify these kinds of symmetries even up to 40 per cent of defect." |

| Source: University of Waterloo | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |