| Posted: Oct 10, 2018 | |

Simple fabrication of full-color perovskite LEDs(Nanowerk News) Perovskite nanoparticles is regarded as next-generation of optical materials that can achieve vivid colors even on very large screens. Besides, due to their high color purity and low cost advantages, it has also gained much interests in industry. |

|

| A recent study (Joule, "Reversible, Full-Color Luminescence by Post-treatment of Perovskite Nanocrystals"), affiliated with UNIST has introduced a simple technique to extract the three primary colors (red, blue, green) from this material. | |

| The video shows the emission color of perovskite nanoparticles changes. These particles emit light when irradiated with ultraviolet rays, and the color can easily be changed by a solution process. | |

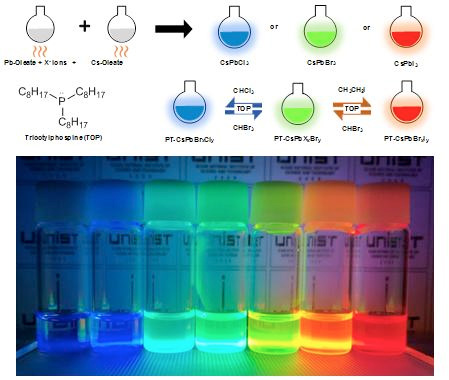

| This breakthrough has been led by Professor Jin Young Kim in the School of Energy and Chemical Engineering at UNIST. In the study, the research team introduced a simple technique that freely controls light emitting spectrums by adjusting the anion halides in perovskite materials. The key is to adjust the anion halides by simply dissolving them in solvents to achieve red, blue, and green lights. Application of this technique to LEDs can result in crystal-clear picture quality. | |

| Perovskite is a semiconductor material with a special structure, containing metal and halogen elements. The solar cell adopting this material is considered to be the next-generation solar cell candidate because it has high photoelectric efficiency that converts sun light into electricity. This material is also attracting attention as a light emitting device because of its high luminous efficiency which turns electricity into light. | |

| Perovskite nanoparticles are microscopic perovskite materials at nanometer (nm, 1 nm / 1 billionths of a meter) level, which emit different colors depending on the internal halogen element. It is a formula that emits red when it is rich in iodine, green when it is rich in bromine, and blue when it is rich in chlorine. | |

| However, perovskite is highly sensitive, making it difficult to change elements stably. In search for an aswer, Professor Kim has developed a simple technique to replace certain elements via solution process. This is a method of inducing element substitution, using nonpolar solvent and chemical additives. | |

| “In the study, we added a nonpolar solvent, containing iodine (I), bromine (Br) and chlorine (Cl) to a solution of perovskite nanoparticles,” says Yung Jin Yoon in the Combined M.S./Ph.D Program of Energy Engineering, the first author of the study. “Once the reaction takes place, the elements mixed within the nonpolar solvent switches its place with elements in original perovskite, which causes changes in luminescence. | |

| The added chemical additive serve to separate the halogen element present in the nonpolar solvent. As a result, the amount of halogen element in the solution increases, and over time, it is replaced with a halogen element in the conventional perovskite. The emission color is determined by the number of elements in the perovskite. The researchers also succeeded in making LEDs with red, blue, and green colors using perovskite nanoparticles made with this technology. | |

|

|

| Kim Ki-Hwan, a research professor in the Department of Energy and Chemical Engineering, said, “It is stable compared to the existing technology to change the element in the solid perovskite.” “It can be applied variously to change the element composition in the perovskite material, I hope it will be possible. ” | |

| “With our simple method, we obtained luminescence covering the entire visible spectrum from 400 to 700 nm,” says Professor Kim. “Furthermore, saturated and vivid RGB LED devices were successfully fabricated using the anion-exchanged nanocrystals.” |

| Source: Ulsan National Institute of Science and Technology (UNIST) | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |