| Posted: Oct 12, 2018 | |

Scientists succeed in controlling the wettability of a nanofiber(Nanowerk News) Researchers succeeded to switch wettability of a nanofiber obtained out of polymers with piezoelectric properties. The time of response to an external trigger was shortened to a few seconds instead of a few minutes at existing methods. For the first time, the scientists managed to control the adherence of droplets to the surface of the material and to make it self-clean. The discovered effects can be used for fluid control in microfluidic devices for chemical and biomedical analysis. |

|

| The research results were published in ACS Applied Materials & Interfaces ("Smart, piezo-responsive PVDF/PMMA surface with triggerable water/oil wettability and adhesion"). | |

|

|

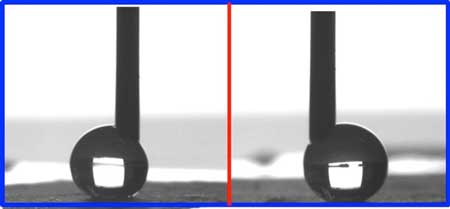

| A drop on the nanofiber. | |

| A novel concept for fluids control on the surface of materials has been proposed by chemists from Tomsk Polytechnic University and the University of Chemistry and Technology (Czech Republic) Researchers succeeded to make the same material superhydrophobic and then hydrophilic very quickly (within seven seconds) compared to existing methods. The rate of reaction to an external trigger is one of the key advantages of the method. Meantime, for the first time the scientists managed to control the adherence of droplets to the surface. | |

| As.Prof. Pavel Postnikov from the TPU Research School of Chemistry & Applied Biomedical Studies tells: ‘One of the most popular and quickly developing trends in materials engineering is the design and realization of so-called smart surfaces. These materials can respond to external stimuli and change their properties. The most important direction here is the control of wettability. Smart materials have a wide scope of applications, e.g. in microfluidic systems for chemical, biomedical analyses, and ecological monitoring. A key drawback of existing methods is the rate. Materials respond to an impulse, for instance, light within a few minutes. For the first time, we managed to achieve an almost instant response by combining physical and chemical methods.’ | |

| The authors of the paper studied two common polymeric materials: ordinary plexiglass (PVDF) and a material with properties similar to Teflon (PMMA). A composite material based on them was chosen due to its piezoelectric properties, i.e. it can stretch or shrink exposed to current. The researchers decided to modify them at fiber level not the surface of polymers. | |

| ‘Our colleagues in Prague dissolve polymers and form nanofibers from the resulting fibers. Then, the fibers are immersed in an aqueous solution with diazonium salts and are thus heated. At the same time, active radicals are formed which attack the surface of the fibers and form the chemical compounds we need, i.e. 4-(perfluoroalkyl) phenyl groups. These compounds together with the physical characteristics of materials make it possible to control wettability. It is important that we work with wettability at the level of each fiber, not at the level of the surface,’ explains Pavel Postnikov. | |

| The scientists bring electrodes to the resulting materials. As soon as the current is supplied, the material immediately changes its properties. Thus, in the superhydrophobic state, it is enough to tilt the plate of the material by three degrees so a drop rolls down from it. The extent of hydrophobicity depends on the intensity of the electric field. Moreover, the researchers observed these effects not only with water but also with lipophilic solvents. According to the authors, this confirms that the methods are suitable for a wide range of liquids. | |

| ‘Another significant property is a self-cleaning surface of the material.If we contaminate it with some substance then we put just a few drops of solvent or water, dirt particles get into water and roll down without sticking to the surface. And it becomes completely clean,’ the scientist says. | |

| Moreover, for the first time, the scientists managed to control the adhesion of drops, i.e. the capability of drops to adhere to a solid surface. | |

| ‘Exposed to electric field a drop is strongly pressed down against the surface. You can even flip the plate and the drop will still stay on it. This suggests that by controlling wettability and adhesion, i.e. changing electrical field, switching current on/off, changing the tilting angle we can control the drop making it move to the required direction. As already mentioned, this is relevant for microfluidic technology as well as, for example, for the creation of biosensors,’ says Pavel Postnikov. |

| Source: Tomsk Polytechnic University | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |