| Oct 22, 2018 | |

Tiny electromechanical devices we use every day could be made from trees(Nanowerk News) From the fitness tracking features of our smart phones to the skid control and navigation on our cars, our daily lives use hundreds, if not thousands, of tiny devices called microelectromechanical systems (MEMS). These MEMS improve our experience of the world in countless ways, but these benefits come at great cost to the environment. |

|

| MEMS production technology, or micromachining, was initially developed to fabricate integrated circuits from silicon. This technology revolutionized circuit miniaturization, allowing powerful computers to shrink from the size of a small house half a century ago to the smart phones we carry in our pockets today. | |

| Silicon MEMS fabrication processes are expensive, energy intensive — reaching temperatures of approximately 1000°C, and utilize hazardous chemicals — such as hydrofluoric acid. The silicon MEMS market is expected to grow to $20 billion by 2020. Much of this growth is due to the increasing demand for biomedical sensors. | |

| In response to this rapidly growing market, concerns are emerging regarding the use of silicon MEMS in terms of cost, scope and potential adverse environmental impacts. | |

| But what if MEMS micromachining was affordable, energy efficient, environmentally friendly, and utilized renewable resources or even waste materials? Auburn University chemical engineers are doing just that. | |

| A recent article in Applied Materials & Interfaces ("Microelectromechanical Systems from Aligned Cellulose Nanocrystal Films") describes how cellulose nanocrystals (CNC) extracted from waste biomass can be used to produce functional MEMS devices with properties similar to those of silicon devices. | |

|

|

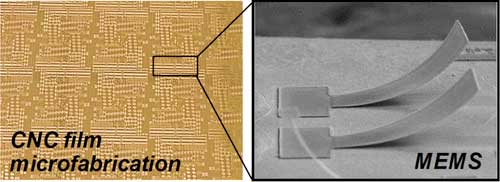

| The team reports that actuatable standard MEMS devices such as cantilever beam arrays, doubly clamped beams, residual strain testers, and mechanical strength testers can be produced via low-temperature fabrication of shear-aligned cellulose nanocrystal (CNC) films. The devices had feature sizes as small as 6 ?m and anisotropic mechanical properties. (© American Chemical Society) | |

| The work was led by the research groups of Auburn University chemical engineering professors Virginia Davis and Robert Ashurst, and their collaborator Clemson University associate professor Christopher Kitchens (who received his Ph.D. from Auburn in 2004). | |

| The low temperatures, primarily aqueous processing, and plasma etching used in this patented process mean that MEMS can now be made from a renewable material using more sustainable processing methods than previously achieved. | |

| Other researchers have sought an alternative to silicon MEMs, but results have been limited by material properties. In contrast, CNC’s outstanding mechanical properties and easy processability have enabled the Auburn and Clemson research team to produce the standard devices and small feature sizes typically included in silicon MEMS. They have also achieved mechanical properties within one third of those of silicon. | |

| In addition, the fabrication method enables more tunable optical and mechanical properties that can be achieved with other materials, and the surface chemistry can be tuned to enable applications requiring immersion in fluids. | |

| “Not only does this technology provide a more sustainable route for meeting the needs of the growing MEMS device and sensors market, it can enable companies to enter the market or develop new diagnostics without the significant investment and time required for traditional MEMS production. This will be critical to our ability to rapidly develop and deploy new diagnostics for emerging needs ranging from mosquito borne viruses, other diseases and emerging contaminants in our food and water supply,” said Davis. | |

| Thus far the research has resulted in two patents available for licensing and been funded by the National Science Foundation, the Auburn University Research Initiative on Cancer, and the Auburn LAUNCH Research and Innovation Fund. Future research is focused on applying the technology to two specific challenges in biological and chemical detection. Specifically, the research team is interested in rapid, simple and simultaneous detection of multiple cancer biomarkers and detection of the evolving range of emerging contaminants in the food and water supply. |

| Source: By Virginia Davis, Auburn University | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |