| Dec 27, 2018 | |

Silver nanowires promise more comfortable smart textiles(Nanowerk News) In a paper to be published in the forthcoming issue of NANO ("Capillarity-Driven Self-Assembly of Silver Nanowires-Coated Fibers for Flexible and Stretchable Conductor"), researchers from the Nanjing University of Posts and Telecommunications have developed a simple, scalable and low-cost capillary-driven self-assembly method to prepare flexible and stretchable conductive fibers that have applications in wearable electronics and smart fabrics. |

|

| A simple, scalable and low-cost capillary-driven self-assembly method to prepare conductive fibers with uniform morphology, high conductivity and good mechanical strength has been developed by a team of researchers in Nanjing, China. Dr. Yi Li and Yanwen Ma, from the Key Laboratory for Organic Electronics and Information Displays, Institute of Advanced Materials (IAM) of Nanjing University of Posts and Telecommunications and his collaborators have developed a simple, scalable and low cost capillarity-driven self-assembly route to produce silver nanowires (Ag NWs) coated flexible and stretchable conductive fibers. | |

|

|

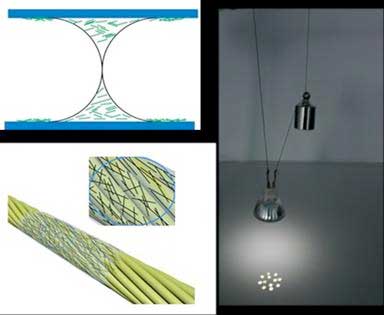

| A simple, scalable and low-cost capillary-driven self-assembly method has been developed to prepare conductive fibers with uniform morphology, high conductivity and good mechanical strength. By coating highly conductive and flexible silver nanowires on the surfaces of yarn and PDMS fibers, high-performance fiber-shaped flexible and stretchable conductors are fabricated, which have great potential for application in wearable devices. | |

| Taking advantage of the capillary action of fibers, such as cotton, nylon and polyester yarns as well as PDMS fibers, the solution containing Ag NWs is spontaneously absorbed into the capillary tunnels. Then Ag NWs are evenly coated onto the fibers through evaporation-induced flow and capillary-driven self-assembly process to form conductive fibers, which is in situ observed by the optical microscopic measurement. | |

| The fabricated flexible and stretchable conductor exhibits uniform morphology, high conductivity and good mechanical strength, which is promising for the application in wearable electronics and smart fabrics. | |

| Conventional conductive fibers are metal wires such as stainless steel and copper wires, as well as the metal film coated yarn. These conductive fibers are stiff and brittle, not meeting the demand of flexibility and comfortability for smart textiles. | |

| Smart textiles with electronic devices such as sensor, light emitting diode, transistor, battery and supercapacitors integrated into fabrics have drawn considerable attention. Conductive fibers and yarns, with the function of connecting various electronic devices, play a key role in smart textiles system. Recently, conductive nanomaterials such as metal nanomaterials, carbon nanotubes and graphene with high conductivity, good mechanical properties, feasibility of large-scale production and solution-process, have become a new type of fundamental materials for conductive fibers. | |

| Great efforts have been made to engineer conductive nanomaterials into conductive fibers by various technologies such as vapor deposition, electrospinning and spray coating methods. Despite these promising progresses, the facile, large-scale and cost-effective fabrication of conductive fibers with high flexibility and good electrical conductivity is still a challenge. |

| Source: World Scientific | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |