| Jan 28, 2019 | |

Aerosol-assisted biosynthesis strategy enables functional bulk nanocomposites(Nanowerk News) In the movie Avengers: Infinity War, one of the coolest scenes occurs when Iron Man activates his nanotech armor and controls nanoparticles to form the armor upon his skin. Actually, developing such a technique to assemble nanomaterials into macroscopic bulk materials that maintain their unique nanoscale properties is still a challenging task for scientists in the real world. Meanwhile, it is also a core issue that hampers the practical industrial application of nanomaterials. |

|

| One possible solution is to provide a skeleton that can hold the individual nanomaterials together and thus construct functional bulk nanocomposites, just like the steel reinforcing bars in reinforced concrete. | |

| Among numerous candidates, bacterial cellulose (BC) nanofibrils, one of the most abundant biomaterials that can be produced in large quantities at low cost via bacterial fermentation, are favored by scientists not only for their high tensile strength that is comparable to steel and Kevlar, but also for the robust 3D nanofibrous network they form. | |

| However, the conventional process of BC nanocomposites fabrication requires the disintegration of such a 3D network structure, which seriously impairs the mechanical properties of the constructed nanocomposites. Up to this point, scientists can't help but wonder if there is an approach that can get the best of both worlds: incorporating nanoscale building blocks into a BC matrix while preserving the 3D network structure of BC. | |

| In response to this challenge, recently, researchers led by Professor YU Shu-Hong from the University of Science and Technology of China (USTC) developed a general and scalable biosynthesis strategy, which involves simultaneous growth of cellulose nanofibrils through microbial fermentation and co-deposition of various kinds of nanoscale building blocks (NBBs) through aerosol feeding (intermittent spray of liquid nutrients and NBBs suspension) on solid culture substrates. | |

|

|

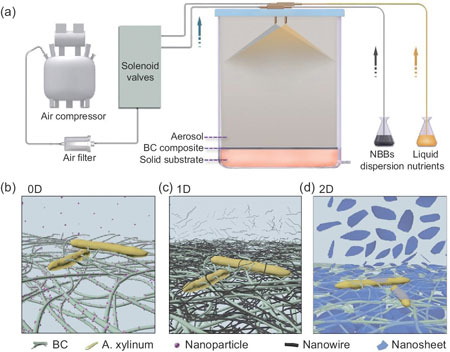

| Schematic illustration of the aerosol-assisted biosynthesis of functional bulk nanocomposites. (a) Scheme of the bioreactor. Aerosols of liquid nutrients and nanoscale building block suspension were fed into the bioreactor with filtered compressed air, which was controlled by an automatic control system. (b)–(d) Schematic illustration of the formation uniform BC-based nanocomposites with 0D nanoparticles (b), 1D nanotubes or nanowires (c), and 2D nanosheets (d). (click on image to enlarge) | |

| Compared with static fermentation in liquid nutrients dispersed with NBBs, this method overcomes the diffusion limitation of nanoscale units from the bottom liquid medium to the upper surface layer of new-grown BC, successfully producing a series of uniform bulk nanocomposites composed of BC and nanoscale building blocks of different dimension, shapes, and sizes. Particularly, the method can be easily scaled up for potentially industrial applications by using large reactors and increasing the number of nozzles. | |

| Thanks to the uniform distribution of NBBs in the biosynthesized nanocomposites, researchers were able to tune the content of carbon nanotubes (CNTs) in a wide range from 1.5 wt% to 75 wt% by changing the concentration of CNTs suspensions. | |

| Note that conventional fabrication method for CNTs nanocomposites that requires the mixing of CNTs dispersions with polymer solutions is only applicable to prepare polymer nanocomposites with low CNTs (< 10 wt%), as it is extremely difficult to homogeneously disperse high-concentration CNTs in polymeric hosts. To further demonstrate the advantages of the biosynthesis strategy for preparing mechanically reinforced nanocomposites, CNTs/BC nanocomposite films were also prepared for comparison by blending of CNTs and disintegrated BC suspensions. | |

| Both the tensile strength and Young's modulus of the biosynthesized CNTs/BC nanocomposites were remarkably higher than that blended samples. | |

| As a result, the biosynthesized CNTs/BC nanocomposites achieve simultaneously an extremely high mechanical strength and electrical conductivity, which is of crucial importance for practical application. nanocomposites. a, Scheme of the bioreactor. | |

| "Despite the fact that we are currently focusing on CNT-based nanocomposite aerogels and films in this work, all the biosynthesized pellicles can be converted into corresponding functional bulk nanocomposites.", says GUAN Qing-Fang, the first author of this work (National Science Review, "A general aerosol-assisted biosynthesis of functional bulk nanocomposites"). | |

| For example, the biosynthesized Fe3O4/BC nanocomposite films exhibited superparamagnetic behavior and high tensile strength, which are expected to be useful in various fields such as electromagnetic actuators, smart microfluidics devices, and biomedicine. "By upgrading the state-of-the-art production line that produces pure bacterial cellulose pellicles, industrial-scale production of these bulk nanocomposite materials for practical applications can be expected in the near future.", the researchers provide a positive outlook. |

| Source: University of Science and Technology of China | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |