| Jun 27, 2019 | |

Thermoelectric nanomaterial turns waste heat back into electricity(Nanowerk News) Some of the vast amount of wasted energy that machines and devices emit as heat could be recaptured using an inexpensive nanomaterial developed at KAUST. This thermoelectric nanomaterial could capture the heat lost by devices, ranging from mobile phones to vehicle engines, and turn it directly back into useful electricity (Advanced Energy Materials, "Low-temperature-processed colloidal quantum dots as building blocks for thermoelectrics"). |

|

| The nanomaterial is made using a low-temperature solution-based production process, making it suitable for coating on flexible plastics for use almost anywhere. | |

| “Among the many renewable energy sources, waste heat has not been widely considered,” says Mohamad Nugraha, a postdoctoral researcher in Derya Baran's lab. Waste heat emitted by machines and devices could be recaptured by thermoelectric materials. These substances have a property that means that when one side of the material is hot and the other is cold, an electric charge builds up along the temperature gradient. | |

| A low-temperature method for enabling high-performance thermoelectric materials to recapture lost energy. | |

| Until now, thermoelectric materials have been made using expensive and energy-intensive processes. Baran, Nugraha and their colleagues have developed a new thermoelectric material made by spin coating a liquid solution of nanomaterials called quantum dots. | |

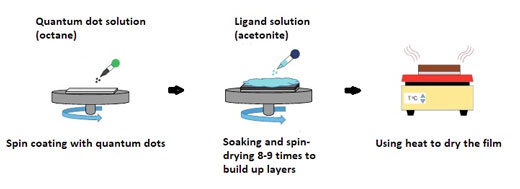

| The team spin coated a thin layer of lead-sulphide quantum dots on a surface and then added a solution of short linker ligands that crosslink the quantum dots together to enhance the material’s electronic properties. | |

|

|

| The team developed a new thermoelectric material by spin coating a liquid solution of nanomaterials and then spin coating a series of thin layers of lead-sulphide quantum dots onto the surface. They dried the film using thermal annealing. (© Wiley-VCH Verlag) (click on image to enlarge) | |

| After repeating the spin-coating process layer by layer to form a 200-nanometer-thick film, gentle thermal annealing dried the film and completed fabrication. “Thermoelectric research has focused on materials processed at very high temperatures, above 400 degrees Celsius,” Nugraha says. The quantum-dot-based thermoelectric material is only heated up to 175 degrees Celsius. This lower processing temperature could cut production costs and means that thermoelectric devices could be formed on a broad range of surfaces, including cheap flexible plastics. | |

| The team’s material showed promising thermoelectric properties. One important parameter of a good thermoelectric is the Seebeck coefficient, which corresponds to the voltage generated when a temperature gradient is applied. “We found some key factors leading to the enhanced Seebeck coefficient in our materials,” Nugraha says. | |

| The team was also able to show that an effect called the quantum confinement, which alters a material’s electronic properties when it is shrunk to the nanoscale, was important for enhancing the Seebeck coefficient. The discovery is a step toward practical high-performance, low-temperature, solution-processed thermoelectric generators, Nugraha says. |

| Source: KAUST | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |