| Oct 09, 2019 | |

How to quickly design a white LED?(Nanowerk News) Lighting is a crucial technology that is used in our daily lives. The advent of the white light emitting diode (LED) that consists of a blue LED with a phosphor layer, greatly reduces the energy consumption for lighting. Despite the fast-growing market, white LEDs are still being designed with slow, numerical, trial-and-error methods. |

|

| A team of scientists from the University of Twente, Technical University of Eindhoven, and leading company Signify (formerly Philips Lighting) introduce a radically new design principle that is based on an analytical model instead of a numerical approach. | |

| The model predicts a white LED�s color point for any combination of design parameters and allows for a much faster design, by up to a 1 000 000 times, resulting in reduced design and production costs. | |

|

|

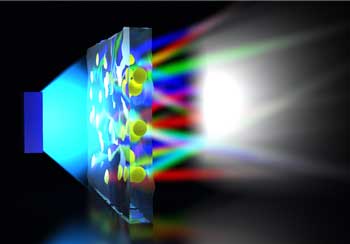

| Figure 1: Schematic of a white LED that consists of a blue semiconductor LED and a layer with phosphor microparticles (yellow spheres). Part of the blue light is scattered and transmitted through the phosphor layer, and part is absorbed and re-emitted in the yellow, green, and red to yield the desired white light. | |

| The results are being published in the leading magazine ACS Photonics ("Systematic design of the color point of a white LED") that is published by the American Chemical Society (ACS). | |

| The main characteristics of a white light source are the color point and efficiency. The color point is defined by the emitted spectrum and it is described by two parameters that span the so-called color space. Optical designers currently use numerical simulations, often based on Monte-Carlo ray tracing techniques to extract the color point, given the design parameters of the white light source. | |

| To aim at a specific color point, optical designers have to use these simulations for each chosen set of design parameters. Unfortunately, simulation methods are very slow and consequently only a small part of the design parameter space can be explored. Hence the design of a white LED relies on the experience of the optical designer rather than on a systematic exploration of the full design parameter space. | |

|

|

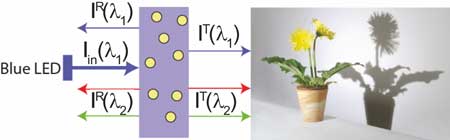

| Figure 2: Blue excitation light with intensity Iin(λ1) that originates from the blue LED is shone on the phosphor slab with thickness L. The phosphor slab contains phosphor microparticles that are represented by yellow circles. IT(λ1) is the scattered transmitted intensity, IR(λ1) is the scattered reflected intensity, IT(λ2) is the transmitted re-emitted intensity, and IR(λ2) is the reflected re-emitted intensity. The mixture of transmitted red, green, and blue light illuminates the object, such as a flower. | |

| An important class of white light sources are white LEDs, which possess numerous advantages over conventional sources, such as incandescent lamps or discharge lamps. White LEDs are among the most energy efficient sources, they are mechanically robust and thermally stable, they possess good temporal stability and they have a long lifetime. | |

| A typical white LED consists of a blue semiconductor LED – for which Akasaki, Amano, and Nakamura received the 2014 Nobel prize – and a phosphor layer that consists of a matrix with phosphor microparticles. | |

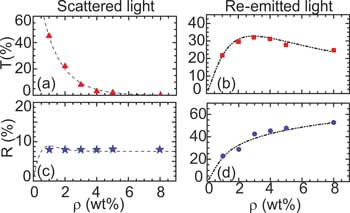

| Part of the blue light is transmitted through the phosphor layer, and part is absorbed and re-emitted in the red and green part of the spectrum to yield the desired white light that illuminates a targeted object or space. The relative amounts of scattered and re-emitted light (Figure 3) define the color point of a white LED. | |

|

|

| Figure 3: Transmission and reflection of a white LED as a function of phosphor particle density (for wavelength l1 = 475 nm). (a) Dashed line represents the calculated total transmission coefficient of the scattered light. Triangles represent the measured coefficient, (b) dash-dot-dot line represents the calculated total transmission coefficient of the re-emitted light. Squares represent the measured coefficients, (c) dashed line represents the calculated reflection coefficient of the scattered light. Stars represent the measured coefficient, (d) dashed-dot line represents the calculated reflection coefficient of the re-emitted light. Circles represent the measured coefficient. The error bars of the experiment are within the symbol size. | |

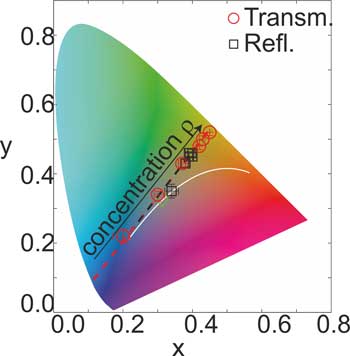

| To adjust the color point several design parameters are available, such as the phosphor particle density r (see Figure 4), the phosphor layer thickness L, the kind of phosphor, the type of blue LED, and additional optical elements. | |

| To systematically design the color point of a white LED, algorithms are needed that are much faster than ray tracing techniques. | |

| Leading author IJzerman from major industry Signify points out: �To date there is no good model to describe scattering in the illumination industry. All our models depend on advanced curve fitting whereby one or more parameters are determined by matching measurements with simulations. To improve this time consuming and costly approach, an a priori model based on physical measurable parameters would be of great value and a major step forward.� | |

| And it is exactly this problem that has now been solved by the Dutch team. | |

|

|

| Figure 4: Color point of a white LED. Circles (transmission) and squares (reflection) are our experimental data points for the wavelength l1=475 nm (see Figure 3). Red and black dashed lines represent predicted color points as a function of the phosphor particle density r (from 1 wt% to 8 wt%) for transmitted and reflected light, respectively (shown in Figure 3). The green diamond indicates the most widely used standardized white light spectrum, the D65 spectrum. | |

| The Dutch team introduces an extremely fast and analytic computational tool - based on the so-called P3 approximation to the radiative transfer equation. | |

| Lead author Vos enthuses: "we are able to predict the color point of a white LED starting from the chosen design parameters. Conversely, we can get the design parameters of a white LED starting from a targeted color point.� | |

| IJzerman points out: �In this new situation, the inverse problem does not require an iteration procedure for each new design cycle. Given the speed of our tool, we can generate � once and for all - a look-up table for the whole parameter space available to engineers. Thereby, we obtain tremendous speed and efficiency benefits.� | |

| Lagendijk adds: �I am excited that white LEDs will further contribute to a fast globalization of lighting, and thus to worldwide literacy and democratization. This is relevant to regions where a few solar cells are readily available, and where extensive electricity grid is too expensive or tedious�. | |

| Previously, the team showed how to precisely determine essential parameters of phosphors from a few measurements ("Tracing light inside an LED leads to higher efficiency"). |

| Source: University of Twente | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |