| Apr 09, 2020 | |

Sliding walls - a new paradigm for microfluidic devices(Nanowerk News) Currently, fluidic control in microdevices is mainly achieved either by external pumps and valves, which are expensive and bulky, or by valves integrated in the chip. |

|

| Numerous types of internal valves or actuation methods have been proposed, but they generally impose difficult compromises between performance and fabrication complexity. | |

| In new work (Microsystems & Nanoengineering, "Sliding walls: a new paradigm for fluidic actuation and protocol implementation in microfluidics"), researchers from Laboratoire Physico Chimie Curie, Institut Curie, PSL Research University in Paris, propose a new paradigm for actuation in microfluidic devices based on rigid or semi-rigid walls with transversal dimensions of hundreds of micrometres that are able to slide within a microfluidic chip and to intersect microchannels with hand-driven or translation stage-based actuation. | |

|

|

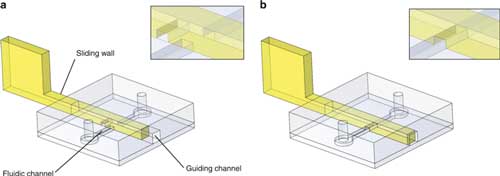

| Sliding wall principle. PDMS structures contain a guiding channel and a fluidic channel and were bonded to a planar PDMS surface. In this example, a sliding wall with an engraved channel was inserted after chip fabrication inside the guiding channel. The fluidic channel was a) blocked or b) free. Details of the sliding wall/fluidic channel intersection are provided in the inserts. (© Microsystems & Nanoengineering) (click on image to enlarge) | |

| With this new concept for reconfigurable microfluidics, the implementation of a wide range of functionalities was facilitated and allowed for no or limited dead volume, low cost and low footprint. The researchers demonstrate here several fluidic operations, including on/off or switch valving, where channels are blocked or reconfigured depending on the sliding wall geometry. | |

| The valves sustain pressures up to 30 kPa. Pumping and reversible compartmentalisation of large microfluidic chambers were also demonstrated. This last possibility was applied to a “4D” migration assay of dendritic cells in a collagen gel. | |

| Finally, sliding walls containing a hydrogel-based membrane were developed and used to concentrate, purify and transport biomolecules from one channel to another, such functionality involving complex fluidic transport patterns not possible in earlier microfluidic devices. | |

| Overall, this toolbox is compatible with “soft lithography” technology, allowing easy implementation within usual fabrication workflows for polydimethylsiloxane chips. This new technology opens the route to a variety of microfluidic applications, with a focus on simple, hand-driven devices for point-of-care or biological laboratories with low or limited equipment and resources. |

| Source: CNRS | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |