| Jul 16, 2020 | |

Researchers find technique for 3-D printing on the nanoscale that can correct mistakes(Nanowerk News) University of Dayton physics and electro-optics researchers Md Shah Alam, Qiwen Zhan and Chenglong Zhao have created a less expensive 3-D printing method on the nanoscale that can manufacture nanostructures and erase mistakes. |

|

| Nano Letters ("Additive Opto-Thermomechanical Nanoprinting and Nanorepairing under Ambient Conditions") published their findings. | |

|

|

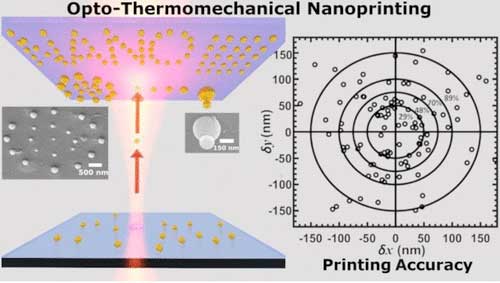

| Different from other existing nanoprinting methods, this method works when a nanoparticle on the surface of a soft substrate is illuminated by a continuous-wave (cw) laser beam in a gaseous environment. The laser heats the nanoparticle and induces a rapid thermal expansion of the soft substrate. This thermal expansion can either release a nanoparticle from the soft surface for nanorepairing or transfer it additively to another surface in the presence of optical forces for nanoprinting with sub-100 nm accuracy. (© Nano Letters) | |

| 3-D printing has been used widely by engineers and designers for years for the rapid prototyping of custom projects, but until now, 3-D printing on a nanoscale was costly, challenging and difficult to correct manufacturing mistakes. | |

| "This nano-version 3-D printing technology fills this gap by providing engineers an affordable manufacturing tool for the fabrication of nanostructures and devices, which has become increasingly important for applications that are enabled by nanotechnology," said Zhao, an assistant professor of physics and electro-optics. | |

| The research team found this process to be less expensive than commonly available nanofabrication techniques that need to be conducted in a vacuum. This new technology utilizes a low-cost laser, such as a laser pointer used in presentations, to transfer nanoparticles from one surface and assemble them on nanodevices on another surface. | |

| Also as important, this technology allows users to correct fabrication errors that occur during the manufacturing process, Alam, a graduate student of electro-optics, added. | |

| "Manufacturing error correction is extremely important to reduce manufacturing cost and increase the success rate of a production line," said Zhan, a professor of electro-optics. "For example, before, if a tiny manufacturing error is found in an electronic chip, the entire chip has to be discarded. This technology will enable us to correct manufacturing errors even after manufacturing." |

| Source: University of Dayton | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |