| Jul 30, 2020 | |

A crazier crazy straw for science(Nanowerk News) What do the loopy straws that children like to sip drinks through have in common with cutting-edge science? Ask Ryan Murphy and his colleagues at the National Institute of Standards and Technology (NIST), where the team has thought up a creative way to explore the properties of fluids under extreme conditions. |

|

| The team invented a device that can push fluids through a narrow tube at the velocity of a car hurtling down a rural interstate — about 110 km per hour. This might not sound overly fast to a road tripper, but the tube’s inner diameter is typically 100 micrometers — about the thickness of a human hair. Scaled up, that would be like a train hurtling through a subway tunnel about 100 times faster than a rocket blasting its way into orbit. | |

| To add to the fun, the meter-long tube is coiled up like a spring, so the fluid careens around loop after three-centimeter-wide loop, as though that rocketing subway were a blindingly fast roller coaster that turns somersaults from start to finish. | |

|

|

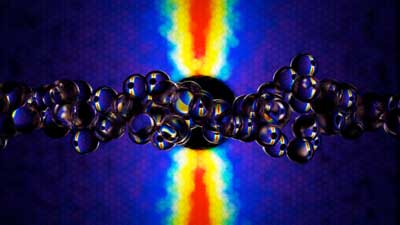

| In this artist’s conception, data from the small angle neutron scattering (SANS) experiment at the NIST Center for Neutron Research (NCNR) form a colorful backdrop to transparent spheres representing part of a worm-like micelle, a tiny structure often found in soaps. Higher-intensity neutron scattering (red regions) indicates that the micelles are aligning strongly with the direction of flow through the NCNR’s capillary rheoSANS device, lining up like toothpicks in a tube. The micelles are one of many substances whose properties under extreme flow conditions could become better understood with the new research tool. (Image: R. Murphy/NIST) | |

| Installed at the NIST Center for Neutron Research (NCNR), the team’s device is about to do some serious science, with a potentially big payoff for many industries. The companies that have signed on to use the device range from drug makers and oil prospectors to chemical manufacturers. All of these businesses make or use fluids that contain complex substances such as nanoparticles, and the companies need to know what happens to the fluids’ structure as they get forced through narrow passages at high pressures. | |

| That’s just what the device, called the Capillary RheoSANS, is made to explore. The NCNR produces streams of neutrons, which bounce off complex molecules in telltale ways that reveal their structure to an instrument called the small-angle neutron scattering (SANS) detector. The coiled tube is set up so that a neutron beam passes through it and the fluid it carries. The curlicues in the tube aren’t there to give the fluid a thrill ride; they keep the fast-moving liquid exposed to the neutron beam long enough to get useful data. | |

| The conditions in the tube mimic those that a medicine experiences as it is injected through a needle, or shampoo as it squirts out of its bottle cap. Fluids may only experience such conditions for a brief time period, but for complicated and sometimes fragile materials, that can be enough to affect their flow-related, or rheological, properties — sometimes in significant ways. | |

| “We don’t know what the structures of these fluids are at extreme conditions,” Murphy said. “It’s easy to test when they’re moving slowly, but when you pump them out fast at high pressures you want to know what they’re going to do.” | |

| A description of the device and some preliminary studies that show its potential appears in the journal Soft Matter as a featured article ("Capillary RheoSANS: measuring the rheology and nanostructure of complex fluids at high shear rates"). The paper offers examples of what capillary rheoSANS can reveal about fluids’ changes in viscosity, or resistance to flow, at high shear rates. Shear effects appear as a liquid flows quickly along a wall, which slows the parts of the fluid that touch it and causes stress. These effects can distort its ingredients in ways that have been difficult to study until now. | |

| One of the first materials the research team explored was a relatively new class of therapeutic proteins known as monoclonal antibodies (mAbs). These mAb molecules show promise for treating cancer and autoimmune disorders, but scientists are still learning how they behave. Some of them tend to clump up for some reason as they flow, an issue that could compromise the product when it is injected into a patient. | |

| “We measured the mAbs at a high rate that should have deformed or denatured the proteins, but we didn’t see that happening,” Murphy said. “We’re still not sure what is causing the mAbs to clump up over time, but we’ve ruled out the pressure in the needle as the reason. So, we can move on to exploring other potential causes.” | |

| Another substance the team looked at were surfactants (soaps are a common example), which can change the viscosity of oils such as those secreted in your skin. They are commonly used in shampoos, but prospectors also use them for oil and natural gas recovery from hard-to-reach places underground. On a microscopic scale, surfactants form tiny wormlike structures called micelles that align with one another as you pump them through a pipe, but as the flow rate increases, the alignment starts to break down. | |

| “The alignment peaks at a specific point we were able to spot,” Murphy said. “We’ve got some theories as to why it’s happening, and Capillary RheoSANS is helping us to refine them.” | |

| The device came about as a result of a five-year effort supported by NIST’s Innovations in Measurement Science program, which provides funding for “the most innovative, high-risk and transformative measurement science ideas” from NIST researchers. | |

| The Capillary RheoSANS will be available to researchers who visit the NCNR to perform neutron-based experiments, including members of the nSOFT Consortium. The consortium helps deliver technology and expertise to U.S.-based industrial researchers using neutrons to study “soft” materials ranging from biodegradable plastics to composites and biopharmaceuticals. | |

| “We’re excited to help with exploring the properties of complex fluids,” Murphy said. “In the future we’re hoping to find ways to combine our device with X-rays and other types of light, so we can see even more of what’s going on at the nanoscale.” |

| Source: NIST | |

|

Subscribe to a free copy of one of our daily Nanowerk Newsletter Email Digests with a compilation of all of the day's news. |