| Jul 20, 2022 |

Rewriting the history of K-carbon fiber manufacturing with carbon nanotubes

(Nanowerk News) A space elevator, a technology connecting the Earth’s surface to a space station, would allow for the cost-efficient transport of people and materials. However, a very light yet strong material is essential to making such a technology a reality.

|

|

The carbon nanotube is a material that is 100 times stronger, yet four times lighter, than steel, with copper-like high electrical conductivity and diamond-like thermal conductivity. However, previous carbon nanotube fibers were not ideal for extensive use, owing to the small contact area with adjacent carbon nanotubes and limited length they possessed.

|

|

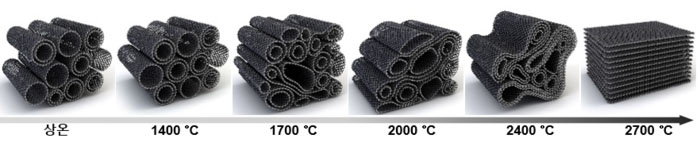

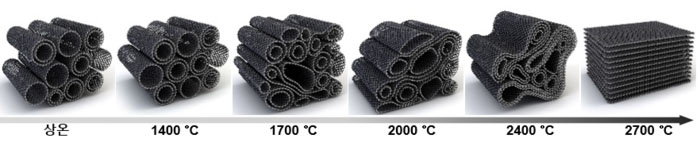

| Figure 1. Schematic of the structural changes of carbon nanotubes at different annealing temperatures. (Image: Korea Institute of Science and Technology)

|

|

A research team led by Dr. Bon-Cheol Ku at the Korea Institute of Science and Technology (KIST) Jeonbuk Institute of Advanced Composite Materials in South Korea announced that it had developed an ultra-high-strength and ultra-high-modulus carbon nanotube fiber material through a joint research project with Professor Seongwoo Ryu’s research team at Suwon University in South Korea, and Dr. Juan José Vilatela from the IMDEA Materials Institute in Spain (Science Advances, "Ultrahigh strength, modulus, and conductivity of graphitic fibers by macromolecular coalescence").

|

|

Existing polyacrylonitrile (PAN)-based carbon fibers have high strength and a low modulus, whereas pitch-based carbon fibers have low strength and a high modulus. Previous studies on simultaneously improving the tensile strength and modulus of carbon fibers only focused on adding a small amount of carbon nanotubes. However, the KIST, Suwon University, and IMDEA joint research team produced fibers entirely consisting of carbon nanotubes without using the conventional carbon fiber precursors, polymer and pitch.

|

|

The team manufactured high-density, high-alignment carbon nanotube fibers through a wet-spin manufacturing process suitable for mass production and then annealed them at high temperatures to enable their structures to be converted into various specific types, including graphite. Accordingly, the contact areas of the carbon nanotubes increased.

|

|

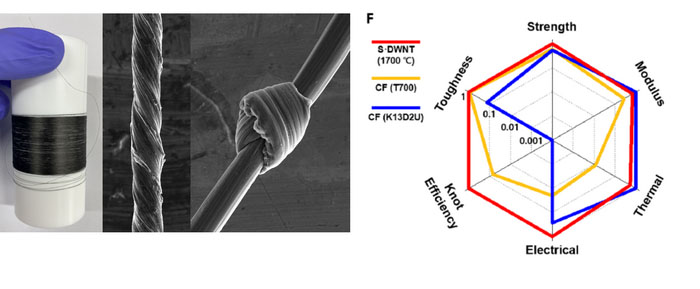

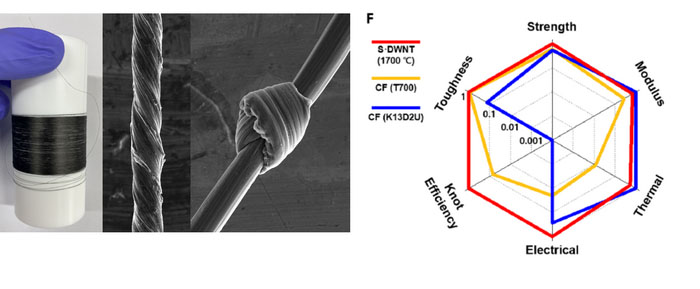

These carbon nanotube fibers produced in such a way are expected to have various applications, as they simultaneously exhibit ultra-high strength (6.57 GPa) and an ultra-high modulus (629 GPa) characteristics, which could not be achieved with conventional carbon fibers. The fibers also showed high knot strength, indicating flexibility (Figure 2).

|

|

| Figure 2. (Left) Continuously manufactured carbon nanotube fibers. (Right) Graph comparing physical properties between carbon nanotube fibers and commercialized carbon fibers. (Image: Korea Institute of Science and Technology)

|

|

Dr. Bon-Cheol Ku commented, “K-carbon fiber manufacturing technology using carbon nanotube materials is what will enable South Korea, a latecomer to the carbon fiber field, to lead the industry. This important technology will serve as the future growth engine for the aerospace and defense industries which is needed to propel South Korea into the realm of materials superpowers.”

|

|

He continued, “We have secured the original technology for manufacturing carbon nanotube-based ultra-high strength and ultra-high modulus carbon fibers, but in order for the mass production of ultrahigh performance carbon fibers to be possible, the mass production of double-walled carbon nanotubes, a core material, must happen first,” stating that support on the national level as well as industry interest are needed to further progress.

|