| Sep 29, 2022 |

Engineers develop ultra-strong aerogels with materials used in bullet-proof vests

(Nanowerk News) Aerogels are lightweight materials with extensive microscale pores, which could be used in thermal insulation, energy devices, aerospace structures, as well as emerging technologies of flexible electronics. However, traditional aerogels based on ceramics tend to be brittle, which limits their performance in load-bearing structures. Due to restrictions posed by their building blocks, recently developed classes of polymeric aerogels can only achieve high mechanical strength by sacrificing their structural porosity or lightweight characteristics.

|

|

A research team led by Dr Lizhi Xu and Dr Yuan Lin from the Department of Mechanical Engineering of the Faculty of Engineering of the University of Hong Kong (HKU), has developed a new type of polymer aerogel materials with vast applicational values for diverse functional devices.

|

|

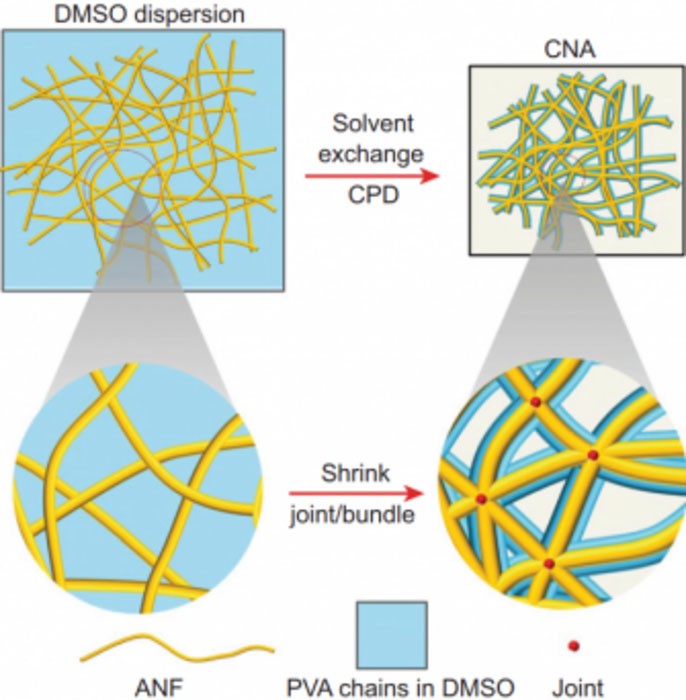

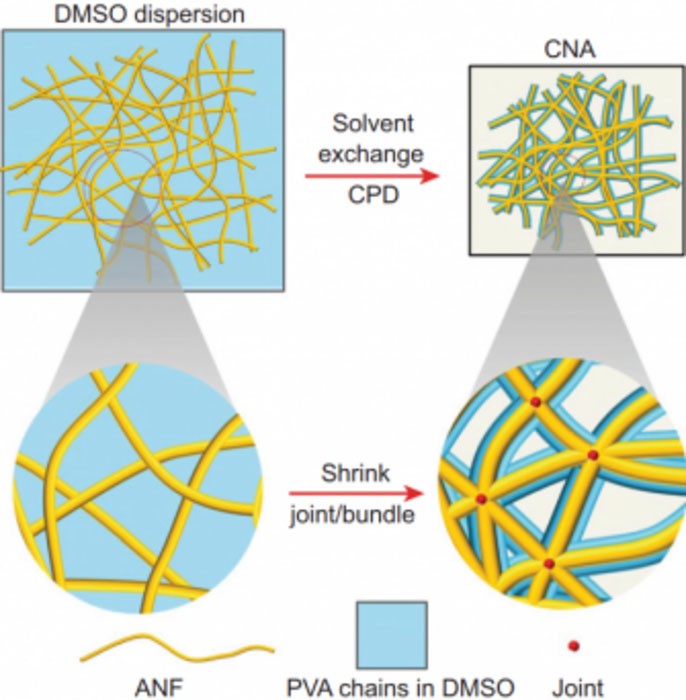

| Schematics of the assembly process of the composite nanofiber aerogels. (Image: The University of Hong Kong)

|

|

In this study (Nature Communications, "Ultrastrong and multifunctional aerogels with hyperconnective network of composite polymeric nanofibers"), a new type of aerogels was successfully created using a self-assembled nanofiber network involving aramids, or Kevlar, a polymer material used in bullet-proof vests and helmets.

|

|

Instead of using millimetre-scale Kevlar fibres, the research team used a solution-processing method to disperse the aramids into nanoscale fibrils. The interactions between the nanofibers and polyvinyl alcohol, another soft and “gluey” polymer, generated a 3D fibrillar network with high nodal connectivity and strong bonding between the nanofibers.

|

|

“It’s like a microscopic 3D truss network, and we managed to weld the trusses firmly together, resulting in a very strong and tough material that can withstand extensive mechanical loads, outperforming other aerogel materials,” said Dr Xu.

|

|

The team has also used theoretical simulations to explain the outstanding mechanical performance of the developed aerogels.

|

|

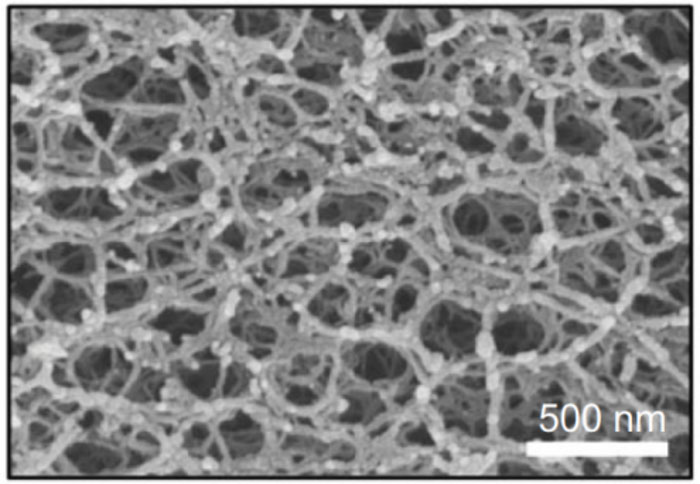

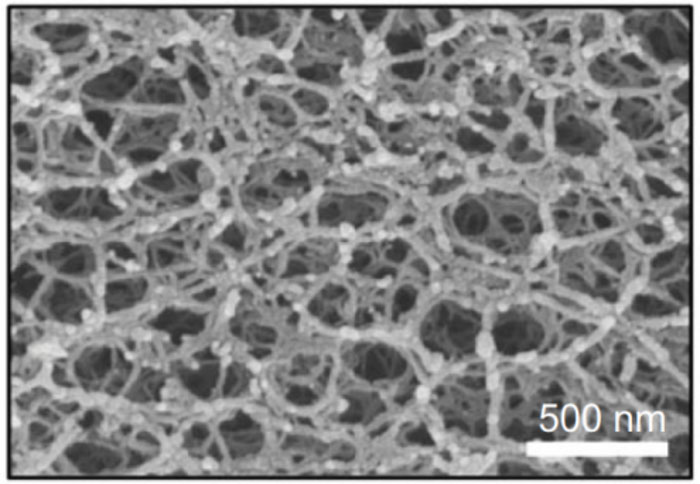

| Scanning electron microscope image showing the micro-structure of the aerogel materials. (Image: The University of Hong Kong)

|

|

“We constructed a variety of 3D network models in computer, which captured the essential characteristics of nanofibrillar aerogels,” said Dr Lin, who led the theoretical simulations of the research. “The nodal mechanics of fibrillar networks are essential to their overall mechanical behaviours. Our simulations revealed that the nodal connectivity and the bonding strength between the fibres influenced the mechanical strength of the network by many orders of magnitudes even with the same solid content,” said Dr Lin.

|

|

“The results are very exciting. We not only developed a new type of polymer aerogels with excellent mechanical properties but also provided insights for the design of various nanofibrous materials,” said Dr Xu, adding, “the simple fabrication processes for these aerogels also allow them to be used in various functional devices, such as wearable electronics, thermal stealth, filtration membranes, and other systems.”

|