| Posted: March 17, 2010 |

Polymer science: A phobia of light |

|

(Nanowerk News) A small volume of water placed on a surface does not flow forever. Molecular-level interactions between the liquid and the solid shape the water into a droplet. Scientists at the Singapore Institute of Manufacturing Technology of A*STAR and Nanyang Technological University, Singapore, have now shown that droplet formation on a polymer can be controlled by exposing the surface to short pulses of light ("Polymer hydrophilicity and hydrophobicity induced by femtosecond laser direct irradiation").

|

|

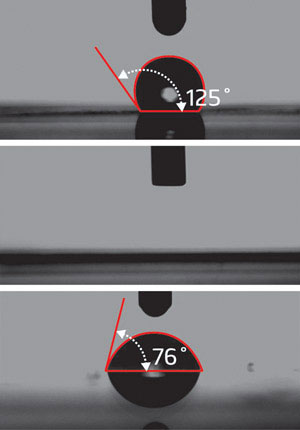

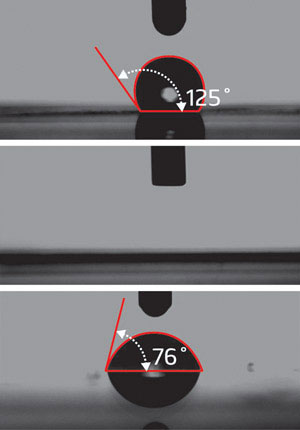

A measure of how well water flows on a specific material, known as the wettability, is given by the internal angle between the droplet wall and the surface. If the water is able to spread thinly, the angle is less than 90° and the material is said to be hydrophilic. A droplet on a hydrophobic surface on the other hand acts to minimize the contact area by forming a tight droplet with an angle in excess of 90°.

|

|

| Fig. 1: A small volume of water placed onto a PMMA surface forms a droplet (bottom) with a contact angle (shown in red) of less than 90°, so the PMMA is called hydrophilic. Exposing the surface to pulses of light can change PMMA’s interaction with water to either superhydrophilic (middle) or hydrophobic (top), depending on the dose. (Image: Zhong Ke Wang)

|

|

In their study, the research team demonstrated that femtosecond-long pulses of near-infrared light can make polymethyl methacrylate (PMMA) either hydrophilic or hydrophobic. They scanned a small area of PMMA with a focused laser beam. The contact angle between the treated surface and a 0.5-microliter droplet of water depended on the energy of the exposure (Fig. 1), which they changed by moving the laser spot in and out of focus. PMMA was super-hydrophilic at the highest exposures investigated, but the contact angle increased as the energy decreased. An optical dose of 2.1 joules per square centimeter or less made the polymer hydrophobic, and the maximum internal angle achievable was 125°. “Laser irradiation is a promising method to control surface wettability. It offers significant flexibility because it enables selected areas to be modified at a high speed,” explains Zhong Ke Wang, the lead researcher on the study.

|

|

To understand the underlying cause of the variation in wettability, the scientists used X-ray photoelectron spectroscopy to see how the light affected the way atoms in the polymer bonded. High exposures increased the number of carbon–oxygen double bonds at the expense of carbon–carbon single bonds. The double bonds are known, from previous research, to promote hydrophilicity.

|

|

PMMA is perhaps better known under the trade names Perspex or Plexiglas. One of its numerous applications is in microfluidics, where liquid flows in channels just a few micrometers across. Altering the interaction of PMMA and water could enable new functionality in microfluidic circuits. “Surface wettability affects the flow velocity and enables the separation or mixing of liquid samples into different channels,” says Wang.

|

|

The A*STAR affiliated authors in this highlight are from the Singapore Institute of Manufacturing Technology.

|