| Posted: March 31, 2010 |

Spray-on manufacturing of transistors with organic semiconductors |

|

(Nanowerk News) A multidisciplinary research team at the National Institute of Standards and Technology (NIST) has found that an organic semiconductor may be a viable candidate for creating large-area electronics, such as solar cells and displays that can be sprayed onto a surface as easily as paint ("High performance airbrushed organic thin film transistors").

|

|

While the electronics will not be ready for market anytime soon, the research team says the material they studied could overcome one of the main cost hurdles blocking the large-scale manufacture of organic thin-film transistors, the development of which also could lead to a host of devices inexpensive enough to be disposable.

|

|

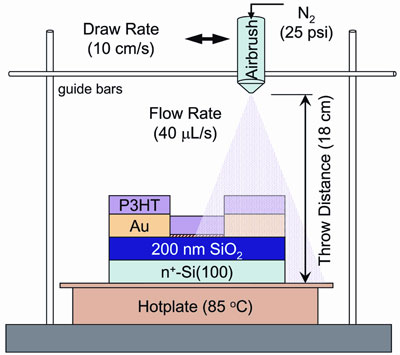

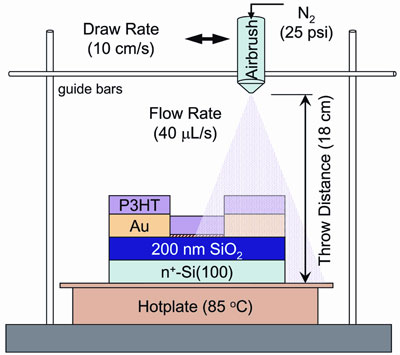

| This airbrush technique deposits a well-studied material called P3HT to create spray-on transistors, which perform comparably to lab-standard equivalents made by spin coating.

|

|

Silicon is the iconic material of the electronics industry, the basic material for most microprocessors and memory chips. Silicon has proved highly successful as a substance because billions of computer elements can be crammed into a tiny area, and the manufacturing process behind these high-performance chips is well-established.

|

|

But the electronics industry for a long time has been pursuing novel organic materials to create semiconductor products—materials that perhaps could not be packed as densely as state-of-the-art silicon chips, but that would require less power, cost less and do things silicon devices cannot: bend and fold, for example. Proponents predict that organic semiconductors, once perfected, might permit the construction of low-cost solar cells and video displays that could be sprayed onto a surface just as paint is.

|

|

“At this stage, there is no established best material or manufacturing process for creating low-cost, large-area electronics,” says Calvin Chan, an electrical engineer at NIST. “What our team has done is to translate a classic material deposition method, spray painting, to a way of manufacturing cheap electronic devices.”

|

|

The team’s work showed that a commonly used organic transistor material, poly(3-hexylthiophene), or P3HT, works well as a spray-on transistor material because, like beauty, transistors aren’t very deep. When sprayed onto a flat surface, inhomogeneities give the P3HT film a rough and uneven top surface that causes problems in other applications. But because the transistor effects occur along its lower surface—where it contacts the substrate—it functions quite well.

|

|

Chan says the simplicity of spray-on electronics gives it a potential cost advantage over other manufacturing processes for organic electronics. Other candidate processes, he says, require costly equipment to function or are simply not suitable for use in high-volume manufacturing.

|