| Posted: July 29, 2010 |

A proposed flow battery for grid-scale storage gets $1.6 million from ARPA-E |

|

(Nanowerk News) Lawrence Berkeley National Laboratory, known for having one of the top research programs in the country for batteries and fuel cells for vehicle applications, has decided to enter another area in the battery world. It has been granted $1.6 million in American Recovery and Reinvestment Act funds to develop a novel storage device for the electric grid.

|

|

The funding comes from the Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E), whose mission is to invest in projects that will develop transformational energy technologies. The award is part of the $92 million announced by ARPA-E this month for "43 cutting-edge research projects that aim to dramatically improve how the U.S. uses and produces energy."

|

|

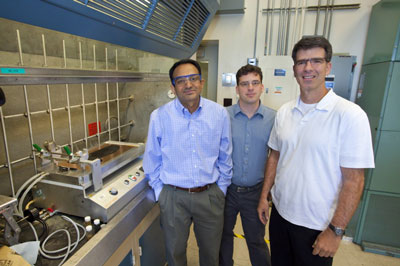

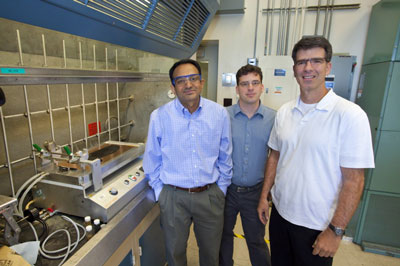

| (from left) Venkat Srinivasan, Adam Weber and Vince Battaglia will develop a flow battery for the electric grid.

|

|

Grid-scale storage would allow grid operators to use more renewable energy, such as wind and solar, which are known as "variable loads" because they are inconstant. A grid-scale battery could collect all the energy generated when, say, the wind blows during sunrise and sunset and then discharge during the rest of the day, allowing the grid to distribute the energy when demand is higher. Without such storage capabilities, operators struggle to balance supply with demand on the instantaneous basis people expect.

|

|

To meet the grid's storage needs, the Berkeley Lab team has proposed a flow battery using hydrogen-bromine chemistry. "At the end of the project, we expect to have a high power, high efficiency, long life, low cost, safe storage device," says Berkeley Lab scientist Venkat Srinivasan, the lead investigator on the project.

|

|

Flow batteries are different from conventional batteries in that the energy and power are separated. In this way, flow batteries are similar to fuel cells and are also analogous to a car, where the internal combustion engine provides the power and the fuel tank provides the energy. To get faster acceleration, or more power, one can simply increase the size of the engine, and to increase the range, one can increase the size of the tank.

|

|

Similarly, a flow battery has a reactor that provides the power and external tanks that store the chemical reactants which provide the energy. "This is one advantage over traditional batteries: you have some degree of scalability," says Srinivasan. "To get more energy, you can increase the tank size. If you use very cheap chemicals, even if the reactor is expensive, the overall cost per unit of energy comes down because the energy scales with the volume of chemicals."

|

|

The Berkeley Lab team, which also includes scientists Vince Battaglia and Adam Weber, is supported by a team of major private-sector partners to help develop other components of the flow battery. One critical task is to synthesize a novel, low-cost membrane. The membrane essentially separates the cathode from the anode and prevents reactants from mixing while still providing good conductivity. The team decided to look to chemical giant DuPont.

|

|

"We needed somebody very good in membranes to work with us because we're not experts in that area," says Srinivasan. "DuPont is the world leader in ion-exchange membranes."

|

|

For the catalyst, Berkeley Lab is teaming with the Bosch Group to come up with a new, cheaper material to catalyze the electrochemical reactions. Because platinum, the metal commonly used as a catalyst in fuel cells, is expensive and may be prone to deactivation by bromine, the scientists will be looking for alternative cheaper metals. 3M, which makes an advanced nanostructured thin film electrocatalyst, is also a partner in the project.

|

|

For the electrochemical reactions, hydrogen and bromine are both inexpensive chemicals and, together, a hydrogen-bromine system has been shown to provide good efficiency, high power and reversible reactions. Reversibility is essential because a flow battery must charge as well as discharge. However, because bromine gas is toxic, another task in this project is to find ways to minimize or eliminate the production of bromine gas by modifying the electrolyte.

|

|

While the technical challenges present some risk, Srinivasan, Battaglia and Weber intend to take advantage of everything scientists have learned from fuel cell advances in the last 20 years and apply them to flow batteries, which generally have not been able to achieve high efficiencies. At the end of this ARPA-E funded two-year project, Berkeley Lab hopes to have a proof-of-concept for a flow battery that will have a high round-trip efficiency of 80 percent and cost less than $100 per kilowatt-hour of energy.

|

|

Even if hydrogen-bromine turns out not to be the "winning" combination for a flow battery, Srinivasan says: "That is not so important. What we bring to the table is not the chemistry, but a group of people that have expertise to solve all these problems, irrespective of the chemistry. We'll be developing the skill sets in the next couple of years to understand the fundamentals of flow battery operation. We'll have the ability to go forward and work with any chemistry."

|