| Posted: August 31, 2010 |

Micro rheometer is latest lab-on-a-chip device |

|

(Nanowerk News) Researchers at the National Institute of Standards and Technology (NIST) have demonstrated a microminiaturized device that can make complex viscosity measurements—critical data for a wide variety of fields dealing with things that have to flow—on sample sizes as small as a few nanoliters. Currently a table-top prototype, the NIST rheometer could be a particularly valuable tool for biotechnologists studying minute quantities of complex materials that must function in confined spaces.

|

|

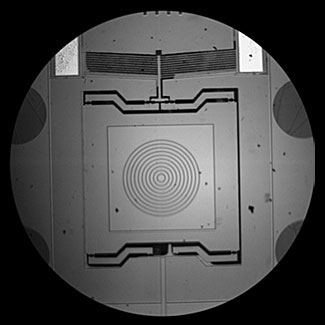

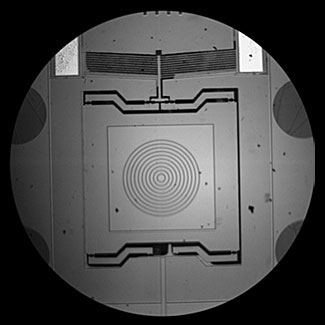

| The NIST MEMS-based rheometer (click to retrieve mpg file of the device in action.) The moving plate is controlled by resistance heating elements in the chevron-like structure at the top; expansion and contraction of the vanes causes the plate to move up and down. Central square where the sample would rest is approximately 500 micrometers across.

|

|

Viscosity, elasticity and how materials flow when subject to a force is the subject of rheology, and the measurements tell a lot about a complicated material like a gel. Is it more like a liquid or a solid? By how much and under what conditions? The popular toy Silly Putty™ is a classic example of complex viscoelasticity, bouncing better than a rubber ball under a sharp, sudden force but slumping into a puddle when left alone.

|

|

One common way to make dynamic rheology measurements (how behavior changes with the speed or frequency of the applied force) is with a sizeable lab instrument that traps a test sample between a fixed plate and one that moves, and measures how much the thin layer of test material resists being deformed. Typical sample sizes are around a couple of milliliters, which doesn't sound like much, but, says polymer scientist Gordon Christopher, for some researchers it's a whole bunch.

|

|

"A lot of people in the biosciences are making very complex designer fluids based on proteins where you might make only 10 milliliters at a time. Polypeptide hydrogels for drug delivery or tissue replacement, for example," Christopher explains. "Their flow behaviors are very complicated and you really need to understand them, but in a traditional rheometer your sample for a single test is a large percentage of what you just spent two months making."

|

|

Inspired by a talk by a NIST scientist working on the design of novel nano positioning microelectromechanical systems (MEMS), team leader Kalman Migler and his colleagues began a collaboration to build a MEMS device that duplicated a classic sliding-plate dynamic rheometer—but in a space about one-twentieth the size of a postage stamp. The sample size of the MEMS rheometer is about 5 nanoliters. "With our device, if you gave me a milliliter of sample, I could give you back hundreds of tests," Christopher says.

|

|

Equally as important, he says, the MEMS rheometer inherently tests materials when they are confined in a very small space. For many biological applications where the material is meant to be used in a confined region like a blood vessel or the interior of a cell—or must be injected through a thin needle—understanding the flow characteristics of small amounts in a small space is more important than knowing how it behaves in bulk.

|

|

NIST's early prototype MEMS rheometers include only the core sliding plate mechanism on the MEMS chip, and rely on a microscope and high-speed cameras for the actual measurements. In a more polished version, according to the research team, the necessary sensors could be included on the chip and the entire instrument reduced to a handheld device for, e.g., quality control measurements on a plant floor. The NIST MEMS dynamic rheometer is described in a new paper in Lab on a Chip ("Development of a MEMS based dynamic rheometer").

|