| Posted: Sep 15, 2010 |

|

Microfluidics: A step in the right direction

|

|

(Nanowerk News) Microfluidic devices are great tools for producing fine droplets or emulsions. Most microfluidic devices make use of either a cross-flow or flow-focusing junction — the former produces droplets by crossing two streams of immiscible liquids, say oil and water; the latter achieves the same result by flowing two immiscible liquids through a narrow channel.

|

|

Tae Goo Kang and co-workers at the A*STAR Institute of Microelectronics have now designed and fabricated a range of silicon-based microfluidic devices that make use of a stepwise flow-focusing junction to generate droplets of tunable size and emulsion characteristics ("The shape of a step structure as a design aspect to control droplet generation in microfluidics").

|

|

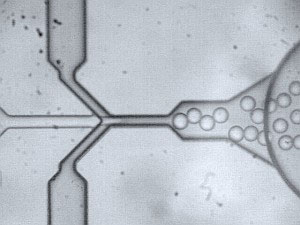

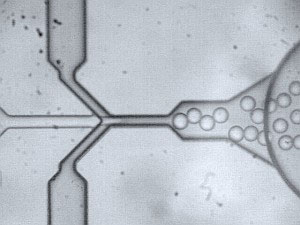

| Fig. 1: A microscopy image of a new type of microfluidic device that can produce microdroplets of a specific size by modifying the geometry of a stepwise flow-focusing junction (left of center). Flow is from left to right, and the channel width is 200 µm.

|

|

To make the microfluidic device, Kang's team used a deep reactive-ion etching tool to cut micrometer-deep trenches in a silicon wafer. They then used an oxygen plasma ashing and silicon isotropic etching tool to polish the edges of the trenches, and finally capped the device with plain glass or hard plastic. Through this strategy, they were able to create microfluidic devices with 'microchannels' that meet at a stepwise flow-focusing junction (Fig. 1).

|

|

The new microfluidic devices can generate droplets over a broader range of flow rates than conventional devices, and the size of the droplets can be tuned by fabricating junctions with different shapes. For example, a wedge-like junction produces smaller droplets, while a flat T-like junction produces larger droplets.

|

|

In general, hydrophilic surfaces favor the production of oil-in-water droplets, whereas hydrophobic surfaces favor the formation of water-in-oil droplets. The researchers noticed that microfluidic devices capped with hydrophilic plastic produced oil-in-water droplets. They expected this to happen because the plastic and the microchannel walls (made of silicon) were both hydrophilic materials.

|

|

The researchers noticed, however, that microfluidic devices capped with hydrophobic plastic produced water-in-oil droplets, despite the hydrophilic nature of the microchannel walls. The surface properties of the capping material appeared to dictate the type of droplets formed. Further investigation showed that the stepwise geometry of the flow-focusing junction is responsible for this effect.

|

|

The researchers expect their microfluidic devices to find applications in many industries, especially for the manufacture of stable emulsions, because of the uniformity of droplets they produce.

|

|

"We believe that the results of this work can improve the quality of emulsions in food, pharmaceuticals and cosmetics," says Kang. "Apart from direct applications, we are currently moving towards biomedical applications, for example, capturing a single nucleic acid in the microdroplets and making millions of copies of it for further biological analysis. In such applications, the precise generation of microdroplets is crucial."

|