| Posted: Nov 04, 2010 |

|

AIST develops revolutionary products using clay films

|

|

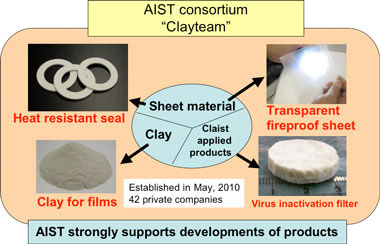

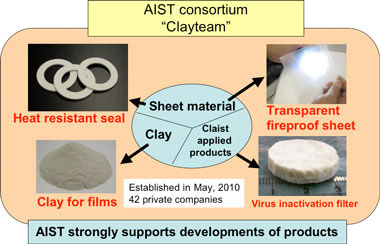

(Nanowerk News) Takeo Ebina, Advanced Functional Materials Team, the Research Center for Compact Chemical System of the National Institute of Advanced Industrial Science and Technology (AIST), et al. have developed high-performance multifunctional sheets and a raw material of a clay film in collaboration with the private companies that are members of "Clayteam," an AIST consortium, formed in May 2010.

|

|

The developed items are (1) a heat-resistant seal material for gaskets used in power plants, chemical plants, etc. that covers the entire temperature range of conventional products using asbestos [Japan Matex Co., Ltd. (Japan Matex); President: Katsuro Tsukamoto], (2) transparent fireproof sheets with excellent mechanical strength to be used as protective covers for LED lighting and solar cells [Miyagikasei Co., Ltd. (Miyagikasei); Representative Director: Nobuyasu Oyama], (3) photocatalyst-clay filters for cleaning the air in the living space and medical institutions that are effective in inactivating influenza viruses [A&A Material Corporation (A&A Material); President: Mitsuto Shigetomi], and (4) clay for water-vapor-barrier films to be used as damp-proof sheets for solar cells [Kunimine Industries Co., Ltd. (Kunimine Industries); President: Yasuhiko Kunimine].

|

|

These achievements are the results of technology transfer of AIST's clay film technology to the private enterprises. The companies and AIST will continue collaborating with the aim of commercializing the products within six months to two years.

|

|

The details of the technologies will be presented at the 2nd Clayteam Seminar held on September 14, 2010 at Sendai. Further, some information about the technologies will be presented at the AIST Open Lab held in Tsukuba on October 14 and 15, 2010.

|

|

| Figure 1: Development of clay-film-based products realized through the consortium "Clayteam"

|

|

Social Background of Research

|

|

Recently, novel film materials in which clay is the main component have attracted attention. Because of the characteristics of clay, these materials have excellent gas-barrier properties and heat and fire resistance. Hence, such materials are expected be used in heat-resistant seals, gas-barrier films, transparent fireproof films, and hydrogen seal materials.

|

|

In the past, AIST collaborated with individual private companies in the research and development of the clay films, but there was no sufficient comprehensive collaboration including sharing of the know-how that covers raw materials, film fabrication and processing methods, and applications of the films. In addition, there were technical difficulties and cost-related issues involved in the commercialization of the clay films as general-purpose materials. Hence, there was the need for closer cooperation among research organizations and private companies.

|

|

History of Research

|

|

AIST succeeded in developing a clay film, "Claist®," in which clay crystals were used as the main raw materials. Since then, AIST has been conducting the research on the practical applications of the film in cooperation with universities and private companies.

|

|

To strengthen its collaboration with industry, AIST set up "Claist meeting", a division of an AIST consortium "Green Process Incubation Consortium" in 2008. Universities, private companies, and AIST participated in the division, gained a better understanding of the characteristics and applications of Claist®, and conducted activities including seminars. In May 2010, AIST formed a consortium "Clayteam" to expand the activity of "Claist meeting" and to promote the research and development of materials utilizing the clay films and inorganic nanomaterials. In collaboration with research institutions and private companies that are members of "Clayteam," AIST is carrying out support activities including supply of raw clay materials, transfer of clay film technologies, coordination of collaboration with non-members of the consortium, joint research, and evaluation tests. The activities have accelerated the research and development of the clay films.

|

|

The present research and development is supported by a "Grant for Practical Application of University R&D Results under the Matching Fund Method, "Development of high-performance gasket packing products (FY2008-2010)," of the New Energy and Industrial Technology Development Organization; Miyagi regional resource utilization grant, "Development and fabrication of FRP and Claist composite materials with optical transparency, fire resistance and gas barrier characteristics (FY2009);" and National Federation of Small Business Association product development grant (FY2009), "Development of special clays for water resistant clay films."

|

|

Details of Research

|

|

Due to the collaboration supporting activities of "Clayteam," AIST and private enterprises developed high-performance multifunctional sheet materials and a raw material for a clay film within a short time. The details of each item are summarized below.

|

|

(1) Heat-resistant seal material (in collaboration with Japan Matex) (Fig. 2)

|

|

Asbestos products have been widely employed as gaskets used in piping under high-temperature conditions in many industries. To abolish the use of asbestos, it is necessary to develop asbestos-free products with performance and handling characteristics comparable to those of asbestos products at high temperatures; however, it is difficult to retain the sealing properties and durability of such products at high temperatures. AIST and Japan Matex developed a gasket that can withstand temperatures of up to 420 °C, by coating the surface of an expanded graphite gasket with "Claist®," the heat-resistant clay film. However, at temperatures above 420 °C, the sealing properties tended to degrade in an oxygen atmosphere. Therefore, the development of gasket materials that can withstand severe conditions has been conducted.

|

|

As a result, excellent heat-resistant materials without asbestos were developed using heat-resistant raw materials such as clay and inorganic fibers. Further, a method for producing the materials as seamless sheets was established. The content of organic materials in the sheet was minimized and the heat resistance was improved. The sheets withstand temperatures of up to 550 °C, whereas the existing products are stable only up to 420 °C. The asbestos-free materials have stability over a heat-resistant temperature range of gaskets with asbestos and hence find applications in petroleum refining, petrochemical, power, iron, and paper industries. Thus, these materials are expected to replace asbestos completely in the near future.

|

|

| Figure 2: Prototype gaskets fabricated using a heat-resistant sheet

|

|

(2) Transparent fireproof sheet (in collaboration with Miyagikasei) (Fig. 3)

|

|

Currently, there is increased demand for fireproof, transparent, light-weight, and safe materials that can be used as indoor/exterior building materials, vehicle materials (trains and cars), interior materials, and materials for lighting installations. The characteristics are also important for the protective covers of LED, which are becoming increasingly popular. However, it is difficult to develop transparent, incombustible, fracture-proof materials.

|

|

We have developed new transparent fireproof sheets by combining the clay film technology of AIST and the molding technology for glass-fiber-reinforced plastics (GFRPs) of Miyagikasei. This fireproof sheet is a composite material, in which the GFRP surface is covered with a clay film and has excellent optical transparency and incombustible properties (the sheet does not burn even when exposed to a flame at 700 °C for 20 minutes). The lightness and fracture resistance of this sheet are comparable to those of GFRPs. The sheets are expected to be used as transparent fireproof materials, solar cell covers, and light-diffusing covers for LED lighting in various fields including architecture, railroad and automobile, aviation and space, and energy.

|

|

| Figure 3: Transparent fireproof sheet with excellent optical transparency and light-diffusing properties

|

|

(3) Photocatalyst-clay filter (in collaboration with A&A Material)

|

|

While many materials have been developed for use in air-cleaning applications in the living space, materials with better activity and adsorption performance are still desired.

|

|

AIST and A&A Material have developed a flexible, heat-resistant, transparent, and air-permeable photocatalyst-clay filter by combining a photocatalyst with clay. The developed filter is a porous flexible sheet made mainly with clay and shows adsorption performance due to clay. In addition, many holes penetrate the sheet along the vertical direction; fine particles of titanium oxide are attached to the inner surface of these holes. Therefore, light irradiated on the filter easily reaches the titanium oxide particles in the sheet, and high photocatalytic activity is achieved. The virus inactivation rate achieved when using this filter under UV irradiation is larger than 99%, as revealed by a test carried out on the influenza virus (H1N1) by an external test organization. Furthermore, the sheet has good adsorbing and decomposing effects on VOCs such as toluene and acetaldehyde. Since this filter is made of inorganic materials, its performance is presumed to remain stable even after long-term UV irradiation.

|

|

(4) Clay for water-vapor-barrier films (in collaboration with Kunimine Industries)

|

|

Solar cells and various organic devices require materials with excellent water-vapor-barrier properties. Since 2003, AIST has been developing "Claist®SN," a clay film with better heat resistance and water-vapor-barrier properties than those of single-component plastics. To obtain this material, it is necessary to use clay in which the sodium ions have been exchanged with lithium ions. However, the ion-exchanged clay has been produced only in small quantities for experimental purposes, and no practical mass production process has been established to date.

|

|

AIST and Kunimine Industries selected the natural clay best suited for obtaining films, established an effective ion-exchange method, and developed a process for manufacturing the ion-exchanged clay for water-vapor-barrier films. The ion-exchanged clay and a polyimide resin, an additive, were mixed to form a paste, which was subjected to coating, drying, and heat treatment to form a clay film. The gas- and water-vapor-barrier properties of the obtained clay film were sufficiently high to be used as a back sheet for solar cells. Kunimine Industries established a production system that affords a monthly production of several tens of kilograms, in order to meet the demand for clay films in various fields.

|

|

Future Schedule

|

|

We plan to evaluate the performance of the materials and production techniques developed, test their long-term durability, and establish mass production technology, with the aim of commercializing them within six months to two years. In addition, the establishment of a supply system of the clay for water-vapor-barrier films is expected to accelerate the development of practical applications of clay films in various fields.

|