| Nov 10, 2010 |

Microfluidics: A small mix-up

|

|

(Nanowerk News) Microfluidics is the technology of designing and fabricating devices to manipulate tiny streams of fluids. In the past decade, scientists have developed a variety of microfluidic devices for use in chemical synthesis and biological analysis. These microfluidic devices often utilize an intricate network of channels and reaction chambers to mix different types of fluids at a precise ratio. Many studies assess the mixing performance of microfluidic devices using fluids with similar properties — in real-life applications, however, the properties of fluids used can vary tremendously.

|

|

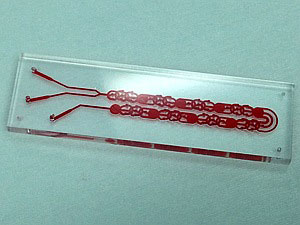

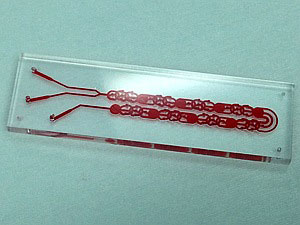

Huanming Xia at the A*STAR Singapore Institute of Manufacturing Technology and co-workers have now developed ("A microfluidic mixer with self-excited 'turbulent' fluid motion for wide viscosity ratio applications ") a microfluidic device for mixing fluids with different viscosities. The microfluidic device features a unique network of interconnected channels and circular chambers that triggers instabilities in the fluid flow (Fig. 1). These instabilities add up to produce a turbulent flow that dramatically improves the mixing of fluids.

|

|

| Fig. 1: Photograph of a microfluidic device for mixing fluids with large viscosity contrast.

|

| The researchers evaluated the performance of their microfluidic device in mixing glycerol and sodium hydroxide (NaOH), fluids with a 680-fold difference in viscosity. They identified changes in the fluid interface as glycerol and NaOH move along the microfluidic device.

|

|

By adding a pH indicator to the glycerol that turns red upon mixing with NaOH, the researchers found that when glycerol and NaOH met up initially, the interface between the two fluids was relatively smooth, meaning that there was little mixing. However, when the fluids entered the interconnected channels, the fluid interface became notably unstable, indicating strong mixing.

|

|

The interconnected channels had parts splitting larger stream of fluids into smaller streams, and parts merging smaller streams of fluids into larger streams. The splitting-and-merging process forced the fluid interface to break up and recombine in a random and chaotic manner. Furthermore, when the fluids entered the circular chambers, the sudden change in flow direction and speed forced the fluid interface to expand and become more unstable.

|

|

"A large viscosity contrast usually retards the mixing of fluids. However, it can be turned into a positive factor as viscous flow instabilities can be produced with specially designed configurations. The current design may be integrated into a microfluidic system to meet the mixing requirements for various applications," says Xia.

|

|

The microfluidic device could mix glycerol and NaOH even at low flow rates. Best of all, the microfluidic device does not require energy to operate and has the benefit of low fabrication cost. The researchers believe that the new microfluidic device will find use in many applications, such as the formulation of polymers, cosmetics, food and beverages.

|