| Feb 08, 2011 |

First successful operation of carbon nanotube-based integrated circuits manufactured on plastic substrates

|

|

(Nanowerk News) As part of NEDO's Industrial Technology Research Grant Japan-Finland collaborative project, Professors Yutaka Ohno from Nagoya University in Japan and Esko I. Kauppinen from Aalto University in Finland along with their colleagues have developed a simple and fast process to manufacture high quality carbon nanotube-based thin film transistors (TFT) on a plastic substrate. They used this technology to manufacture the world's first sequential logic circuits using carbon nanotubes.

|

|

Using this technology, we can expect the development of high-speed roll-to-roll manufacturing processes to manufacture low cost flexible devices such as electronic paper in the future.

|

|

The results were published on February 6th in the electronic edition of the British science journal Nature Nanotechnology ("Flexible high-performance carbon nanotube integrated circuits").

|

|

Background

|

|

Lightweight and flexible devices such as mobile phones and electronic paper are gaining attention for their roles in achieving a smarter ubiquitous information society. For flexible electronics, as a substitute for conventional solid silicon substrates, there is a demand for integrated circuits to be manufactured on a plastic substrate with high speed and low cost .

|

|

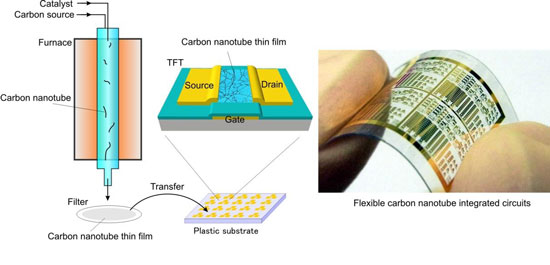

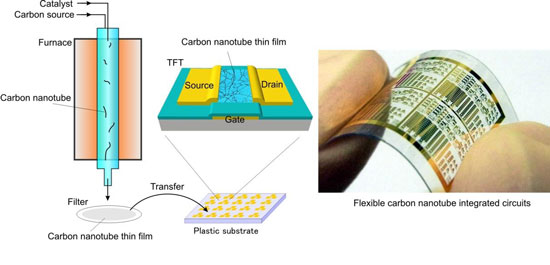

| Fig. 1: Integrated carbon nanotube-based circuit manufacturing on plastic substrates using gas-phase filtration and transfer processes.

|

|

Thus far, flexible thin-film transistors (TFT) have been produced using a variety of semiconductor materials such as silicon and zinc-oxide, which require vacuum deposition, high-temperature curing, and complex transfer processes. In recent years, organic semiconductors have been rapidly developing, however such semiconductors still have low-mobility and there are problems with their chemical stability. Recently, carbon nanotube thin films have been attracting attention due to their chemical stability and high-mobility. However, although simple solution processes have been developed to produce TFTs, such TFTs have not been yet fulfilled capability expectations thus far, due to the deterioration of the conduction properties of carbon nanotube thin films through the dispersion process in the solution.

|

|

Results

|

|

(1) Easy and fast thin film deposition: Gas phase filtration and transfer processes

|

|

In conventional solution processes, soot-like carbon nanotube material is first dispersed in liquid via sonication to purify the materials and to separate the tubes from each other. In such processes, it is difficult to form homogeneous carbon nanotube films. In addition, technology has not yet been developed to completely remove the dispersant. In contrast, using our innovative technology, we continuously grow nanotubes in an atmospheric pressure chemical-vapor deposition process. The nanotubes are then collected on the filter and subsequently transferred onto a polymer substrate using simple gas-phase filtration and transfer processes to achieve clean, uniform carbon nanotube films (Fig. 1). It takes only a few seconds to deposit the carbon nanotubes. This process may be adaptable to high-speed roll-to-roll manufacturing systems in the near future.

|

|

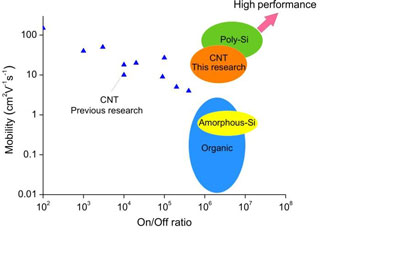

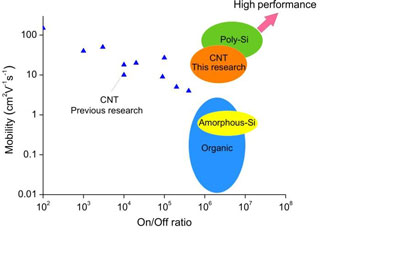

| Figure 2: Performance comparison between carbon nanotubes TFTs and other TFTs (Vertical Axis: mobility, Horizontal Axis: on /off ratio).

|

|

(2) Carbon nanotube TFTs with high-mobility of 35 cm2/Vs and an on/off ratio of 6?106

|

|

In conventional solution-based carbon nanotube TFT manufacturing processes, nanotubes are dispersed using powerful ultrasound which cuts the nanotubes and reduces their length. Due to high contact resistance between these short nanotubes and the residual impurities caused by the dispersion process, the resulting TFT mobility was approximately 1 cm2/Vs. Due to the doping effect caused by residual impurities from the dispersion, the on/off ratio was only between about 104∼105. When carbon nanotube thin films are manufactured using the above gas-phase filtration and transfer processes, the tubes in the film are as clean and long as those that are grown in the synthesis processes. Accordingly, TFTs with a high mobility of 35 cm2/Vs were achieved. In addition, due to precision control of the nanotube density, an on/off ratio of 6x106 was simultaneously achieved. The TFT performance we have achieved is significantly higher than the performance of organic semiconductor TFTs and carbon nanotube TFTs reported so far, as shown in Fig. 2, and equal to the performance of low-temperature polycrystalline silicon as well as zinc oxide TFTs, which are manufactured using high-temperature processes and vacuum-based processes.

|

|

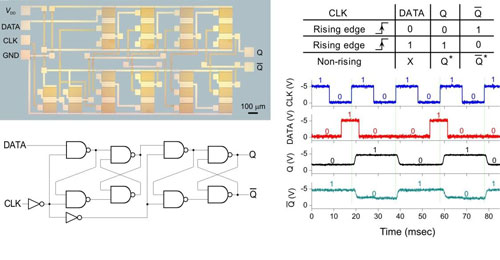

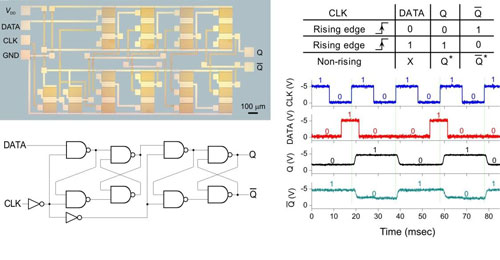

| Fig. 3: Carbon nanotube-based logic integrated circuits on a plastic substrate (master-slave D-flip-flop).

|

|

(3) Successful operation of integrated circuits on transparent and flexible plastic substrates

|

|

The gas-phase filtration and transfer processes can be applied to manufacture devices on any substrate material. This time, we integrated the high-performance carbon nanotube TFTs on plastic substrates, and achieved successful operations of ring oscillators and flip-flops (Fig. 3). High-speed operations have been achieved with a delay time of 12 microseconds per logic gate. The flip-flops that have been manufactured through these processes are the world's first carbon nanotube-based synchronous sequential logic circuits.

|