| May 02, 2011 |

Improved electrical conductivity in polymeric composites

|

|

(Nanowerk News) Physicists at the University of Luxembourg have developed a new method to improve the electrical conductivity of polymeric composites. Polymeric composites consist of two or more materials and are used for example to shield off electrostatics in airplanes. By introducing additives into polymeric composites, favourable properties can be achieved. For instance, they develop favourable electrical properties when reinforced with carbon nanotubes. Such composites are used to make flat-panel displays and solar cells more efficient.

|

|

The researchers in Luxembourg, in cooperation with scientists from the Netherlands, have studied the electrical percolation of carbon nanotubes in a polymer matrix and shown the percolation threshold - the point at which the polymer composite becomes conductive - can be considerably lowered if small quantities of a conductive polymer latex are added. The simulations were done in Luxembourg, while the experiments took place at Eindhoven University.

|

|

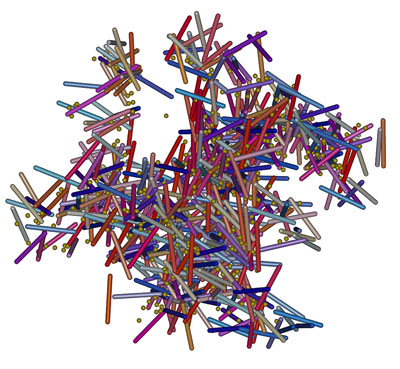

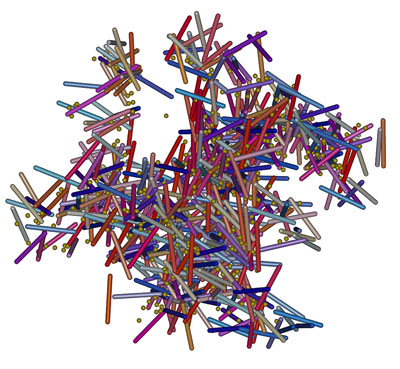

| Percolating network of rods and spheres

|

|

"In this project, the idea is to use as little as possible carbon nanotubes and still benefit from their favourable properties", says the project leader at the University of Luxembourg, Prof. Tania Schilling, "we have discovered that, by adding a second component, we could make use of the resulting interactions to reach our goal." By mixing finely dispersed particles, so-called colloidal particles, of differing shapes and sizes in the medium, system-spanning networks form: the prerequisite for electrically conductive composites.

|

|

The recent finding of the materials scientists of the University of Luxembourg was published in the peer-reviewed, scientific journal Nature Nanotechnology ("Controlling electrical percolation in multicomponent carbon nanotube dispersions"). This finding is a result of a cooperation of scientists at the University of Luxembourg, the Technische Universiteit Eindhoven and the Dutch Polymer Institute.

|