| Aug 19, 2011 |

Screens set to go green

|

|

(Nanowerk News) Fitting the screens of electronic devices, such as televisions and smartphones, with a new display technology called 'organic light-emitting diodes' (OLEDs) will reduce their energy consumption, but such screens currently require rare and expensive metal components.

|

|

Now, Masahisa Osawa and his colleagues at the RIKEN Innovation Center in Wako, along with researchers from electronics company Canon, have found a way to replace these costly metals with copper ("Highly Efficient Green Organic Light-Emitting Diodes Containing Luminescent Three-Coordinate Copper(I) Complexes").

|

|

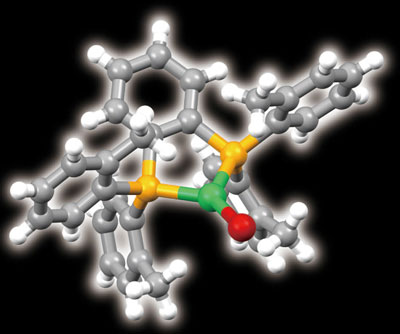

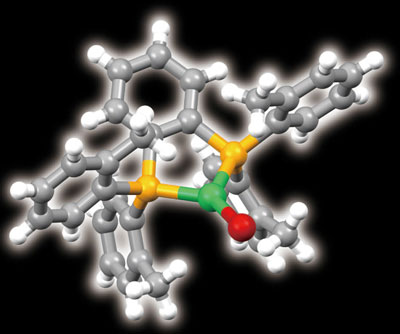

| Figure 1: The molecular structure of the bulky organic ligand that turns copper (green) into an efficient light emitter (yellow, phosphorus; red, bromine). (Image: Masahisa Osawa)

|

|

In addition to offering significant energy savings over conventional LCD-based displays, OLED screens improve picture quality by producing richer blacks; they also offer a wider viewing angle. In an LCD screen, each pixel is effectively a little filter, selectively blocking light produced by a large backlight. In an OLED screen, however, each pixel is a tiny light emitter such that no backlight is needed. This means that pixels in dark areas of the image consume no power, reducing energy use.

|

|

To maximize the energy-saving benefit, screen makers select OLED materials that most efficiently convert electrical current into light, a property known as high external quantum efficiency (EQE). Some of the best materials are phosphorescent metal complexes, but these are typically composed of rare and expensive metals such as iridium.

|

|

Copper complexes have long been known as potential alternatives, and would cost 1/2,000th that of iridium phosphors, according to Osawa. Until the work of Osawa and his colleagues, however, these copper complexes had a low EQE. Such complexes can be readily excited into a high-energy state, but they tend to physically distort, which dissipates their extra energy rather than emitting it as light.

|

|

The researchers resolved this problem by altering the molecular environment in which the copper sits. They wrapped each copper ion inside a newly designed bulky organic ligand. They then conducted X-ray diffraction studies, which revealed that the ligand had forced the copper to become three-coordinate—it had formed three bonds to the ligand, rather than the usual four (Fig. 1).

|

|

Osawa and colleagues also demonstrated that the EQE of their green-light-emitting copper complex increased dramatically and matched that of iridium complexes. "The three-coordinate structure is a crucial factor for high EQE, because it hardly distorts in the excited state," Osawa explains.

|

|

The team's next step will be to deploy the complex in a working device. Copper might not be limited to producing green light, Osawa adds. "Our goal is to make red-, green-, and blue-colored phosphorescent three-coordinate copper materials."

|