| Oct 17, 2011 |

Nanoporous metals: Straight from the template

|

|

(Nanowerk News) Metallic nanoporous materials have a wide range of applications, from catalysts for cleaning pollution to sensors and even light-bending metamaterials. Fabricating such metallic materials with the long-range structural order and precisely controlled pore structure needed for advanced applications, however, remains a challenge. Rong-Ming Ho and colleagues from the National Tsing Hua University in Taiwan with collaborators at Kyoto University in Japan have now devised a 'templated electroless plating' method for creating nanoporous nickel by exploiting the self-assembly of block copolymers ("Nanoporous Gyroid Nickel from Block Copolymer Templates via Electroless Plating").

|

|

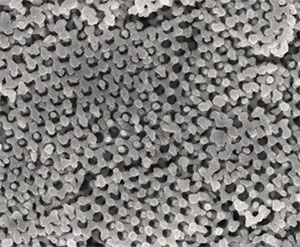

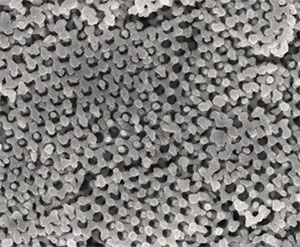

| A scanning electron microscopy image of nanoporous gyroid nickel after removal of the polystyrene template. (© 2011 Wiley-VCH)

|

|

The three-dimensional structure of metallic nanoporous materials is formed by an interconnected network of metal nanoparticles or filaments, resulting in high porosity and high specific surface area. The researchers prepared their nanoporous nickel structures from a network template with a double gyroid structure formed by the self-assembly of block copolymers of polystyrene and poly(L-lactide). After removal of the poly(L-lactide) nanopore network by hydrolysis, a modified electroless plating method devised by Ho and colleagues was used to fill the template with nickel. Their plating method is a self-catalyzing process in which nickel ions are reduced by palladium clusters present in the porous structure. The nickel deposition continues within the pores until all the nanochannels are filled with highly crystalline bulk metal. The polystyrene matrix is then dissolved using an organic solvent, leaving a free-standing, nanoporous gyroid nickel structure (see image).

|

|

The success of the plating step is reliant on the use of optimized reaction conditions, including the right reducing agent, temperature and solvent. The optimal balance of these conditions minimizes the formation of large metal clusters that could block the pores and halt nickel deposition.

|

|

"Nanostructured nickel is a very important catalytic material and widely used in industry," says Ho. "Our nanoporous gyroid nickel material holds great potential for catalytic applications such as supercapacitors, batteries with high power density and hydrogen storage."

|

|

In the future, Ho and his colleagues hope that their templated electroless plating approach can be extended to allow the creation of other metallic nanoporous materials. For example, well-ordered nanoporous metallic structures composed of gold, silver or copper could find uses in surface plasmon resonance applications, or as green catalysts, sensors, actuators and metamaterials.

|