| Mar 15, 2012 |

Imec and Holst Centre develop low-temperature organic-inorganic complementary thin-film technology

|

|

(Nanowerk News) Imec and Holst Centre report the fabrication of high-performance solution-processed n-type metal-oxide thin-film transistors (TFTs) after post-annealing at temperatures as low as 250°C. Using these oxide n-TFTs in combination with pentacene p-TFTs, a completely scalable integration process is developed for hybrid inorganic-organic complementary logic on foil. A bidirectional RFID circuit, recently presented at ISSCC, proves the ability of the technology to realize complex, fast and low-voltage circuitry.

|

|

The development of a thin-film equivalent for Si CMOS circuitry is one of the key objectives of thin-film electronics. Combining n-channel transistors and p-channel transistors in a CMOS architecture allows low static power dissipation, simplified and more robust circuit design and low noise. A very promising approach to realize complementary thin-film logic is to integrate oxide n-TFTs with organic p-TFTs. The preferred technique to make n-type metal-oxide TFTs is solution-based processing, allowing a simple and high-throughput fabrication process. However, solution processing of metal oxides is typically done at high temperatures (350-500°C), making the technique incompatible with flexible substrates such as polyimide.

|

|

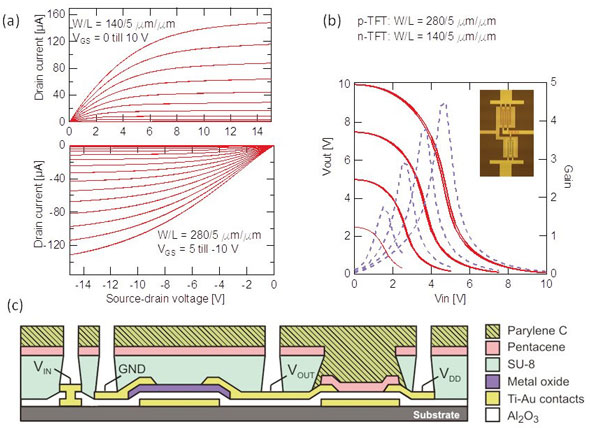

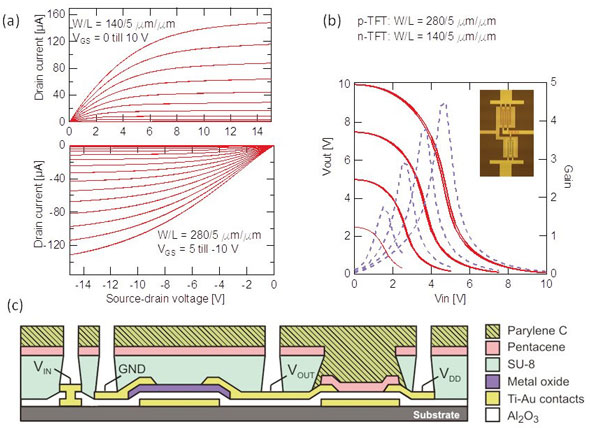

| : (a) Output characteristics of typical solution-processed oxide and evaporated pentacene transistors, (b) inverter characteristics of the hybrid technology at different power voltages. The inset shows a photograph of an inverter. (c) Cross section of the hybrid technology.

|

|

Imec and Holst Centre have now demonstrated high-performance solution-based n-type metal oxide TFTs processed directly on polyimide foil and annealed at 250°C. The n-type indium-based oxide transistors were photolithographically fabricated in a bottom Au gate – top Ti S/D contact geometry with channel lengths down to 2–10µm and 100nm of high-k Al2O3 acting as the gate dielectric. The oxide active layer is deposited by spin-coating and subsequently baked in air at a temperature as low as 250°C. Excellent transistor performances have been achieved on polyimide foil with saturation mobilities exceeding 2cm2/Vs, leakage currents below 1pA and Ion/Ioff ratios up to 108. This solution-based unipolar oxide TFT technology is well suited for application in e.g. active-matrix organic light-emitting diode (AMOLED) backplanes.

|

|

In a next step, a hybrid organic-inorganic complementary technology has been developed that combines the high-performance n-TFT with a thermally evaporated pentacene p-TFT. The latter has a mobility of up to 1cm2/Vs. A gold layer acts as the gate for both the organic p- and inorganic n-TFT, high-k Al2O3 is used to form the dielectric layer. First, the complementary TFT technology was implemented on a rigid substrate. Using this technology, hybrid complementary circuit building blocks, such as inverters and ring oscillators were realized. Supply voltages as low as 2V resulted in good circuit behavior, indicating that the presented technology is suited for future low-voltage applications. This complementary TFT technology enabled to make the world's first RFID circuit (using TFTs) that allows reader-talks-first communication, as recently presented at ISSCC 2012.

|

|

|