| Posted: January 30, 2008 |

Nanotechnology creates new possibilities for plastics |

|

(Nanowerk News) Plastics are among the most notable business segments that benefit from the emergence of nanotechnology, which leads to new creations by controlling matter on atomic and molecular scale.

|

|

Thanks to nanotechnology, the performance of plastics in applications such as molding, films, and packaging, can be enhanced, hence achieving higher efficiency, saving materials, and shortening cycle time.

|

|

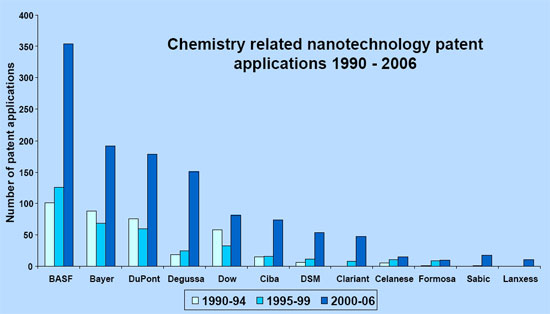

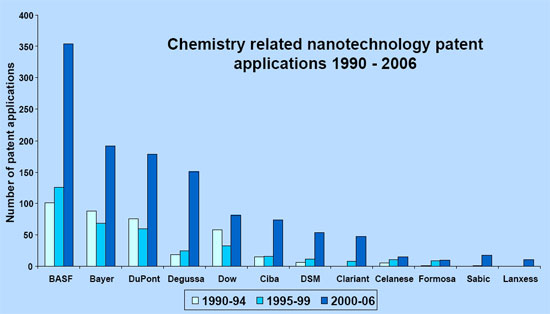

| The number of chemistry related nanotechnology patent applications is fast growing. (Source: BASF)

|

|

Energy saving and shorter cycle time

|

|

BASF's Ultradur polybutylene terephthalate (PBT) can help save energy because it is nano-enhanced. According to Dr Franz Brandstetter, President of Polymer Research of the global leading polymer developer, Ultradur PBT's flowability is doubled by nanotechnology, resulting in lower viscosity, so that processors can use smaller injection and holding pressures while molding, thus achieving energy saving. In addition, low viscosity allows the resin to fill a mold completely.

|

|

High flowability also helps shortening the cycle time. For instance, BASF's Ultradur High Speed, nano-enhanced, helps reduce the cycle time by 30% in the product of air flow meter, Dr Brandstetter says. And in the molding of multiconnectors, the cycle time can be shortened by one-fifth. In addition, using the free flowing Ultradur High Speed, producers of multiconnectors, which usually have a thin-wall structure, can achieve zero product defect, whereas the defect rate can be as high as 5% traditionally, due to the presence of unfilled parts in the mold cavity.

|

|

Thinner insulation building materials

|

|

Nanotechnology also makes thinner insulation building materials possible. The Nanoporous foam features much smaller pores (1,000 times smaller) inside it. These tiny pores allow a much slower rate of heat transfer because such a small size allows very low diffusivity (Knudsen effect). A gas-wall collision is formed, thus stopping the easy passage of heat through the insulation material.

|

|

Increased dirt resistance for plastic films

|

|

With respect to plastic films, nanotechnology, which downsizing hard particles to nano-scale, can raise their performance. According to Dr Brandstetter, with soft polymer matrix encapsulated into hard particles, the film becomes more dirt-resistant and highly adhesive to mineral substrates.

|

|

More appealing sleeves for bottle packaging

|

|

Furthermore, nanotechnology can help to satisfy the demand of the bottle packaging industry for aesthetic sleeves, through the development of angle/stretch dependent colors. Inspired by the butterfly wing texture, sleeves made by nanoparticles get different colors when they are viewed from different angles, or dispersed in color when they are stretched.

|