| Dec 05, 2012 |

Hybrid scaffold more than skin deep

|

|

(Nanowerk News) Open skin wounds need to be repaired quickly to prevent infection. Using artificial skin substitutes for repair avoids the difficulties of grafts, but an ideal material for a scaffold that's strong and allows regeneration of skin tissue has yet to be found.

|

|

Some current scaffolds are made of collagen or gelatin, which are ideal for promoting tissue regeneration but are not mechanically strong. Others are made of biodegradable synthetic materials such as Poly(L-lactic acid) (PLLA); these are stronger, but not so good for tissue growth. Guopong Chen and colleagues at the National Institute for Materials Science, Japan, have created a hybrid scaffold that has all the necessary properties ("PLLA–collagen and PLLA–gelatin hybrid scaffolds with funnel-like porous structure for skin tissue engineering").

|

|

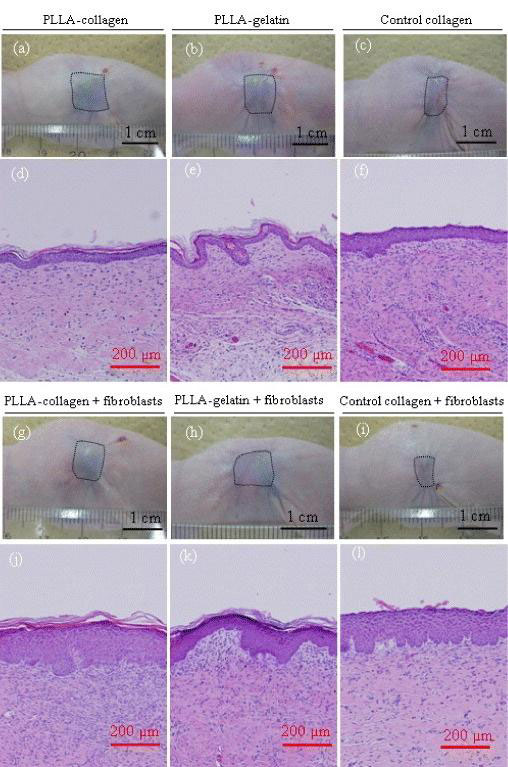

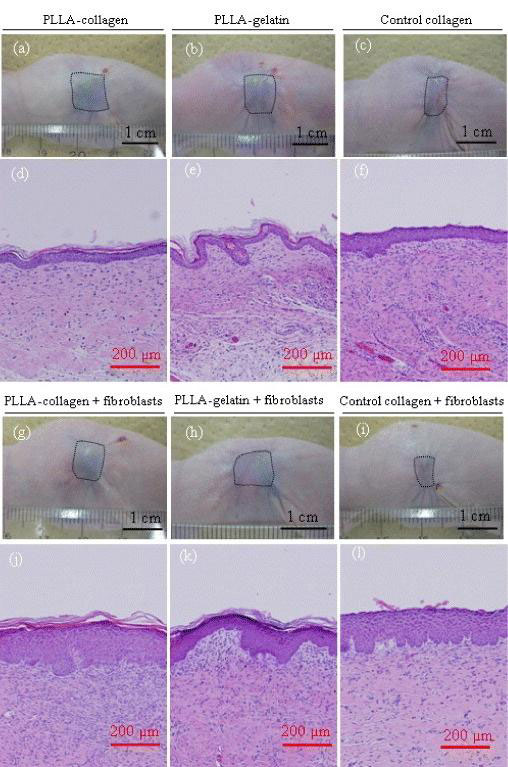

| Gross appearance of the wound closure in athymic nude mice (a–c and g–i) and histological photomicrographs of skin biopsies (d–f and j–l) 4 weeks after implantation. Scale bars represent 1 cm in (a–c, g–i) and 200 µm (d–f, j–l). Wound areas are traced with the dotted rectangles. (Image: National Institute for Materials Science)

|

|

The team had previously formed 'funnel-like' scaffolds with pores that are interconnected under the surface, allowing cells to grow into the scaffold. Now, they have formed these funnel-like collagen or gelatin 'sponges' on a PLLA mesh to create hybrid scaffolds.

|

|

Connective tissue cells grew on the hybrid scaffold and penetrated into the pores, with more cells growing in the hybrid scaffold than in a scaffold made only of collagen. Implantation of the hybrid scaffolds into the backs of mice also promoted healing: four weeks after implantation, skin defects were completely closed. Regenerated skin was healthier with the hybrid scaffold than with a collagen-only scaffold, and there was also less deformation of the skin due to the extra strength provided by the PLLA mesh.

|

|

The ability of the hybrid scaffold to promote regeneration of skin in live animals while maintaining mechanical strength makes it a promising material for future skin tissue engineering.

|