| Jan 22, 2019 |

This small tube could help compress entire laboratories into a computer chip

|

|

(Nanowerk News) Lab-on-a-chip (LOC) technology could transform medicine in ways comparable with how microprocessors have changed our everyday lives – that is once it can be manufactured in a scalable cost-effective way. Researchers in Sweden now report a development that could speed this revolution up.

|

|

A team from KTH Royal Institute of Technology in Stockholm has created a device that precisely dispenses and stores liquids that can be used on a range of diagnostic lab-on-a-chip platforms, at an estimated manufacturing cost of $2 to $6. The technology, which could also be scaled up in size for use in packaging food, cosmetics and chemicals, was reported in Nature Communications ("A micro-dispenser for long-term storage and controlled release of liquids").

|

|

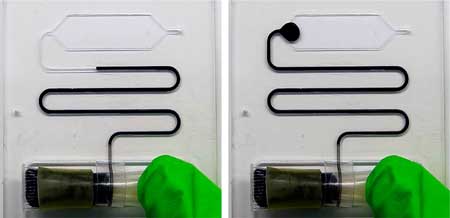

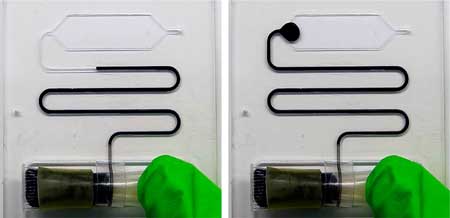

| micro-dispenser for long-term storage and controlled release of liquids. (Image: KTU)

|

|

Aman Russom, professor at KTH’s Science for Life Laboratory research center, says that it overcomes challenges that in many cases make lab-on-a-chip too expensive to be of value outside of research labs.

|

|

Lab-on-a-chip technology promises to transform expensive health care laboratories into small, affordable and portable chips that can perform various tests automatically at points of care. Simpler examples of LOC, such as home pregnancy tests, have already begun this transition to a degree.

|

|

Just as all laboratories rely on storage and dispensing devices, LOC too relies on being able to efficiently store and then release different liquids on a chip. Russom says that the system developed at KTH not only solves and automates these two problems, but can also perform other required techniques, such as filtering, separation and mixing different liquids with minor modification.

|

|

And, importantly, it consolidates these functions on a single device, without the multiple mechanical parts and complex components that today’s dispensers rely on – and which also are costly to produce.

|

|

“We have shown that our simplified micro-dispenser performs different operations without sacrificing scalability or compatibility across different fluidic platforms,” he says.

|

|

The simplified dispenser comprises a tube with an aperture that is covered by an elastic membrane. It’s activated when the internal pressure becomes greater than the force required to stretch the membrane. Pressure can be exerted by pushing with a finger or from the artificial gravity a centrifuge creates. When the internal pressure reaches the critical level, the membrane stretches and provides a path for the liquid to discharge.

|

|

Co-author Amin Kazemzadeh, the researcher who led the development of the device, says the dispenser enables full automation of a variety of clinical tests. “For the first time it enables and automates separation of precise amount of both plasma and red blood cells from a few micro liters to several milliliters of whole blood in portable rotating lab-on-a-chip or centrifugal devices.” He says the device proved accurate in numerous tests with different fluids.

|

|

Lab-on-a-chip devices can be used for performing simple health-related tests such as measuring concentrations of different chemical or biological analytes , such as in blood, plasma or urine.

|

|

“The use of these devices for performing such tests significantly reduces the amount of samples and expensive chemical reagents used, and in many cases shortens the duration of the test from days to less than an hour,” Kazemzadeh says.

|

|

In blood diagnostic tests whole blood is most often separated into its different components. For example, concentrated red cells can be used for measuring hematocrit level and for patients needing oxygen therapy. Plasma is the most important and convenient source of different proteins, fatty acids, hormones, circulating biomarkers and transport cells that can be used for diagnostic of different diseases, such as cancer and infectious diseases.

|

|

Russom and Kazemzadeh say their dispenser may also be valuable in other industries, by extending the shelf life of beverages, chemicals, cosmetics and medicinal substances, which spoil quickly after their packages are opened. “Our technology allows for dispensing liquids without allowing air to enter the container. Therefore, the liquid inside the containers remain intact even after being used. That extends the shelf-life of the content to the nominal shelf-life of the product.”

|