| Feb 23, 2023 |

Learning from mushrooms could help to replace plastics in new high-performance ultra-light materials

|

|

(Nanowerk News) A research group from VTT Technical Research Center of Finland has unlocked the secret behind the extraordinary mechanical properties and ultra-light weight of certain fungi. The complex architectural design of mushrooms could be mimicked and used to create new materials to replace plastics.

|

|

The research results were published in Science Advances ("The complex structure of Fomes fomentarius represents an architectural design for high-performance ultralightweight materials").

|

|

VTT’s research shows for the first time the complex structural, chemical, and mechanical features adapted throughout the course of evolution by Hoof mushroom (Fomes fomentarius). These features interplay synergistically to create a completely new class of high-performance materials.

|

|

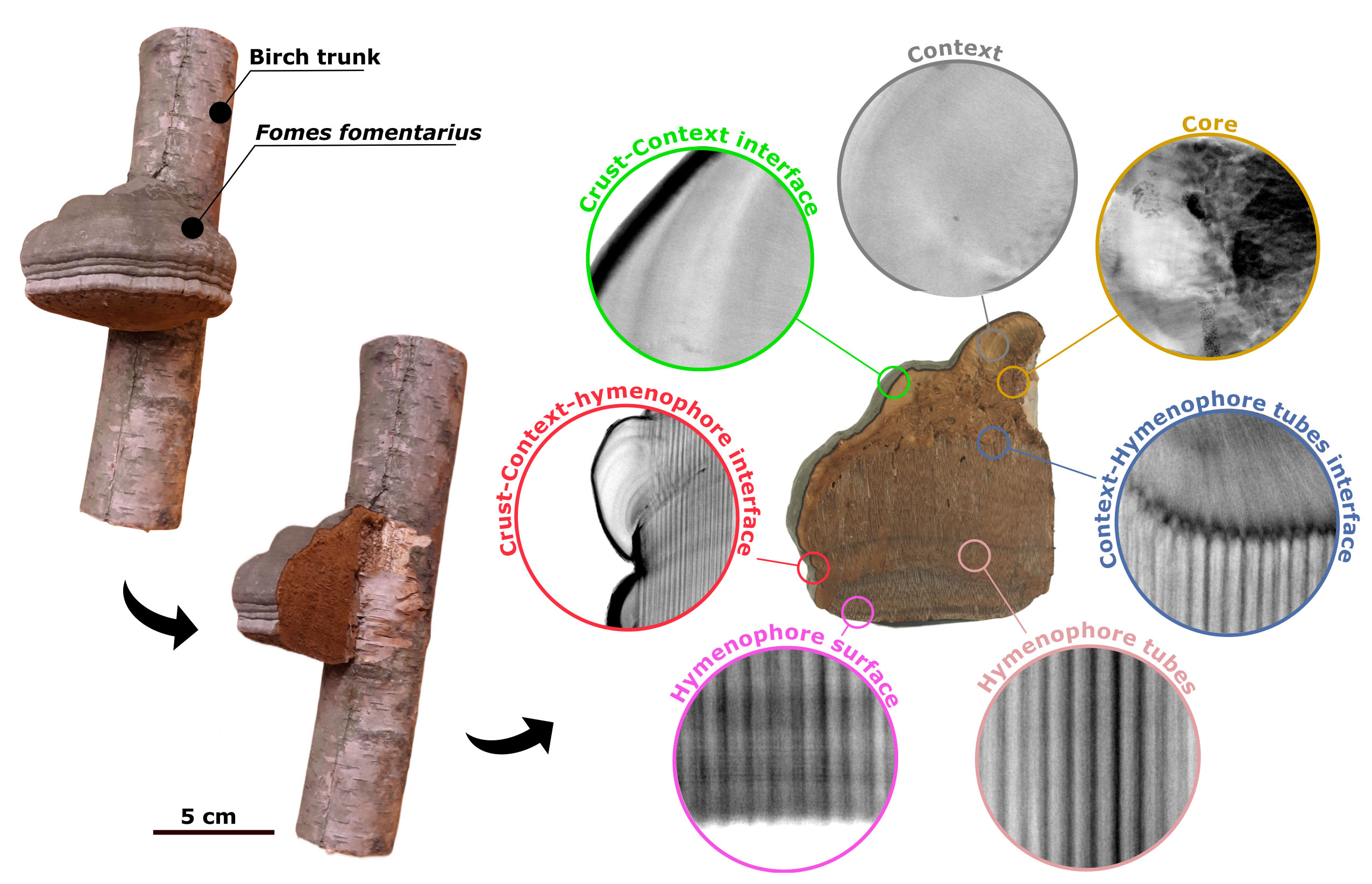

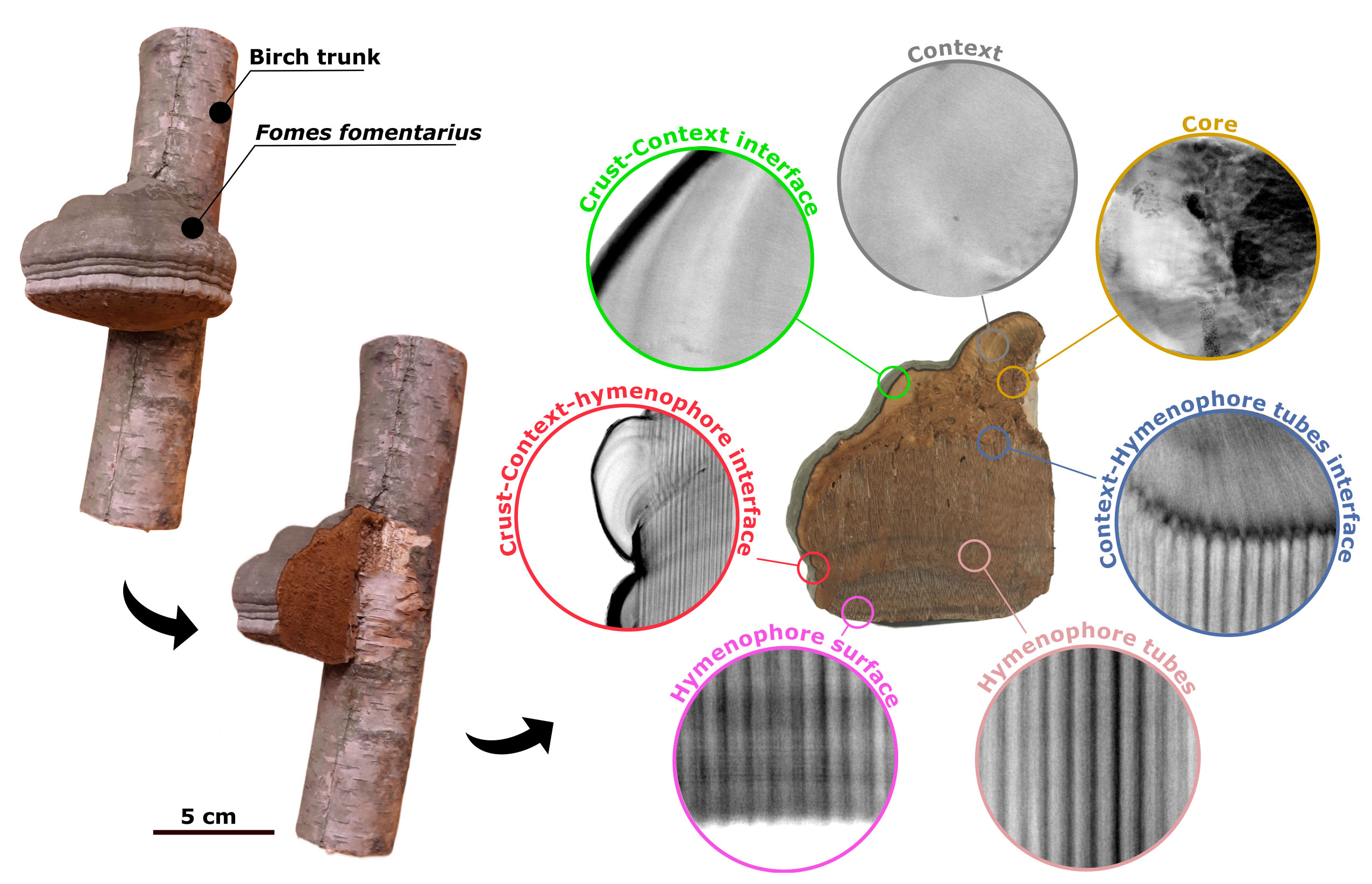

| Illustrative image of Fomes fungus.

|

|

Research findings can be used as a source of inspiration to grow from the bottom up the next generation of mechanically robust and lightweight sustainable materials for a variety of applications under laboratory conditions. These include impact-resistant implants, sports equipment, body armor, exoskeletons for aircraft, electronics, or surface coatings for windshields.

|

Unravelling the unique microstructure of Fomes fungus

|

|

Nature provides insights into design strategies evolved by living organisms to construct robust materials. The tinder fungus Fomes is a particularly interesting species for advanced materials applications. It is a common inhabitant of the birch tree, with an important function in releasing carbon and other nutrients from the dead trees.

|

|

The Fomes fruiting bodies are ingeniously lightweight biological designs, simple in composition but efficient in performance. They fulfill a variety of mechanical and functional needs, for example, protection against insects or fallen branches, propagation, survival (unpreferred texture and taste for animals), and thriving of the multi-year fruiting body through changing seasons.

|

|

VTT’s new research reveals that the Fomes fruiting body is a functionally graded material with three distinct layers that undergo multiscale hierarchical self-assembly.

|

|

“The mycelium network is the primary component in all layers. However, in each layer, mycelium exhibits a very distinct microstructure with unique preferential orientation, aspect ratio, density, and branch length. An extracellular matrix acts as a reinforcing adhesive that differs in each layer in terms of quantity, polymeric content, and interconnectivity”, said Pezhman Mohammadi, Senior scientist at VTT.

|

|

Alterable structure enables different features – source of inspiration for new materials

|

|

The structure of Fomes is extraordinary because it can be modified to create diverse materials with distinct performances. Minimal changes in the cell morphology and extracellular polymeric composition result in diverse materials with different physico-chemical features that surpass most natural and man-made materials.

|

|

While traditional materials are usually confronted by property tradeoffs (e.g., increasing weight or density to increase strength or stiffness), Fomes achieves high performance without this tradeoff.

|

|

“Architectural design and biochemical principles of the Fomes fungus open new possibilities for material engineering, such as manufacturing ultra-lightweight technical structures, fabricating nanocomposites with enhanced mechanical properties, or exploring new fabrication routes for the next generation of programmable materials with high-performance functionalities. Furthermore, growing the material using simple ingredients could help to overcome the cost, time, mass production, and sustainability of how we make and consume materials in the future”, further explain Pezhman.

|