| Nov 27, 2013 |

Materials scientists win award for tiny 3D-printed battery

|

|

(Nanowerk News) Materials scientists at Harvard University have been recognized by the printed electronics industry for their work on novel 3D-printed lithium-ion microbatteries the size of a grain of sand.

|

|

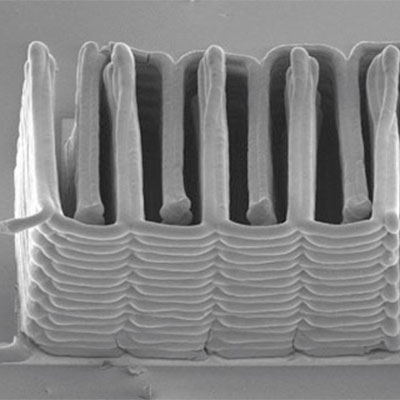

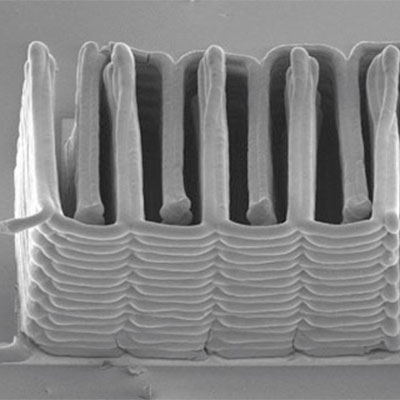

| This image shows the interlaced stack of electrodes that were printed layer by layer to create the working anode and cathode of a microbattery. (SEM image courtesy of Jennifer A. Lewis.)

|

|

The printed microbatteries, which could supply electricity to tiny devices in fields from medicine to communications, received the Academic R&D Award on November 20 at the IDTechEx Printed Electronics USA 2013 event in Santa Clara, California.

|

|

The award, recognizing “innovation, success and development,” was presented to Jennifer A. Lewis, Hansjörg Wyss Professor of Biologically Inspired Engineering at Harvard School of Engineering and Applied Sciences (SEAS), and a Core Faculty Member of the Wyss Institute for Biologically Inspired Engineering at Harvard University.

|

|

The Academic category recognizes researchers who have “made a significant contribution over the past 24 months to the understanding of the principles and accrued knowledge behind printed electronics.”

|

|

According to the award description, Lewis’ research team at Harvard “has printed rechargeable 3D Li-ion microbatteries composed of high–aspect ratio anode and cathode micro-arrays that are interdigitated on a sub-millimeter scale, and exhibit amongst the highest area energy and power densities reported to date. These microbatteries occupy volumes less than 1 mm3—equivalent in size to a single grain of sand—and are 1000 times smaller than the smallest commercially available rechargeable batteries. The university is working on developing these batteries for a broad range of autonomous applications, including biomedical devices, micro-UAVs, and distributed sensor arrays (e.g., smartdust).”

|

|

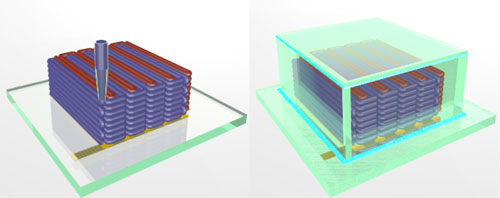

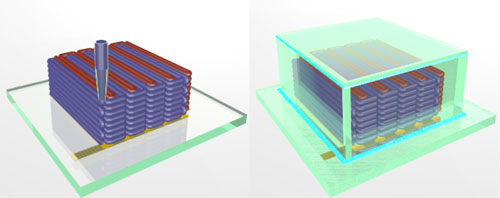

| To create the microbattery, a custom-built 3D printer extrudes special inks through a nozzle narrower than a human hair. Those inks solidify to create the battery’s anode (red) and cathode (purple), layer by layer. A case (green) then encloses the electrodes and the electrolyte solution is added to create a working microbattery. (Illustration courtesy of Jennifer A. Lewis.)

|

|

The work was announced in June 2013 and published online in the journal Advanced Materials ("3D Printing of Interdigitated Li-Ion Microbattery Architectures").

|

|

To create the microbattery, a custom-built 3D printer extrudes special inks through a nozzle narrower than a human hair. Those inks solidify to create the battery’s anode (red) and cathode (purple), layer by layer. A case (green) then encloses the electrodes and the electrolyte solution is added to create a working microbattery. (Illustration courtesy of Jennifer A. Lewis.)

|