| Jul 18, 2013 |

Activated carbon is obtained from sewage sludge

|

|

(Nanowerk News) Researchers at the UPM have discovered how to produce activated carbon from sewage sludge that can be used to purify liquids or gases generated in various production processes.

|

|

The problem involved in gas emissions of greenhouse effect has boosted diverse strategies of capture and storage of the most common gas which is the CO2. A strategy used by the group of Environmental Technology and Industry Resources of the UPM consists of the adsorption of CO2 through activated carbon obtained from sewage sludge ("Carbon dioxide adsorption in chemically activated carbon from sewage sludge"). The use of waste as a raw material to produce activated carbon has a double objective: it allows us to assess the waste as well as reducing the production cost of produced carbon.

|

|

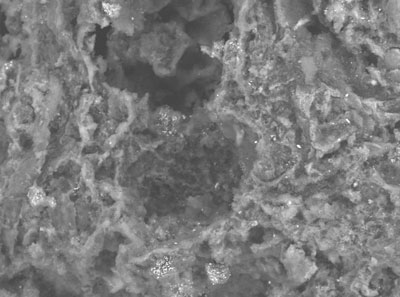

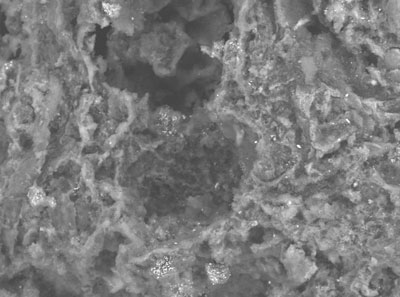

| Pores of activated carbon obtained from sewage sludge.

|

|

The designation of activated carbon includes diverse materials that are generally prepared from wood, coconut shell, coal, lignite and peat and thanks to their high porosity, surface area and superficial chemistry, it can retain a wide variety of substances in their surface. The adsorption is a technique used to retain components that are found in liquids and gases.

|

|

Its main interest is the retained component that can be recovered without altering its properties. With this in mind, the researchers studied the adsorption capacity of CO2 in activated carbon generated from the sewage sludge. Specifically, various activated carbons were produced from sludge previously pyrolyzed (they were treated with heat and no oxygen) by chemical activation with potash (KOH) and soda (NaOH).

|

|

Firstly, they carried out tests of pyrolysis in inert atmosphere of nitrogen under different temperatures. The purpose of these tests was to find out what conditions can benefit further development of porosity. Once the pyrolized material is obtained, researchers carried out the chemical activation with liquid solutions of KOH and NaOH as well as with solid KOH and NaOH, to modify the surface and to increase the porosity of activated carbon and its adsorption capacity.

|

|

Even though porosity of the activated carbons produced from sludge was lower than a conventional activated carbon, the real adsorption of CO2 was quite similar. This can be explained by the fact that surface chemistry of activated carbon plays a relevant role in adsorption processes.

|

|

A part of the gas that is retained in the activated carbon can do it by superficial chemical attraction. The use of some chemicals as NaOH in the activation processes can benefit the generation of active points on the surface of the activated carbon where the CO2 is chemically adsorbed.

|

|

Although activated carbons produced from sludge might not have the same adsorbent properties than conventional active carbons, they have sufficient capacity of adsorption to be used in purification treatment of certain gases.

|