| Mar 15, 2013 |

Nanotechnology's potential impact on the printing industry

|

|

(Nanowerk News) Nanographic Printing™ technology – developed by Benny Landa – also called Nanography, differs from other printing technologies because it uses an innovative system and printing process that employs Landa NanoInk™, a proprietary water-based ink with nano-pigment particles that measure tens of nanometers in size.

|

|

Unlike lithography, Nanographic Printing™ technology harnesses the advantages of digital printing, including shorter turnaround times, reduced waste, the ability to print runs as short as one copy, as well as variable data printing. At the same time, it also offers offset qualities.

|

|

Whereas inkjet printing jets transfer the image directly onto the substrate, Nanography™ first ejects the

NanoInk dispersions onto a unique heated blanket, and only then is the ink transferred from the blanket to

the substrate in the form of an ultra-thin film. This document demonstrates how Nanography achieves the

combined versatility and short-run economics of digital printing with the qualities and productivity of offset

printing.

|

|

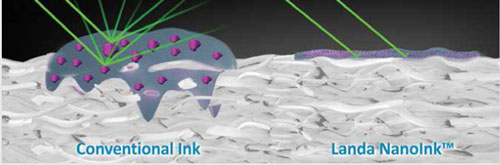

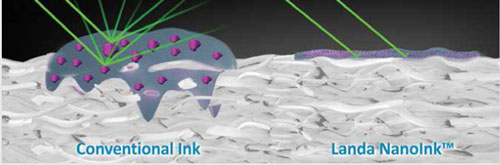

The Landa Nanographic Printing process is innovative in that it utilizes the nano-sized pigments to absorb much more light than other pigments, and thus permits images with ultra-sharp dots of extremely high uniformity, high gloss fidelity and a broad CMYK color gamut – covering at least 15% more Pantone colors than offset printing.

|

|

| Light absorbance comparison: conventional ink vs. Landa NanoInk™ formulations.

|

|

Many of the advantages of the Landa Nanographic Printing process are achieved by eliminating the absorption of the liquid ink carrier by the substrate.

|

|

In addition, the ultra-small Landa NanoInk pigments – and their ability to form a very thin layer of ink – allow digital printing at very high speeds; the ability to print on ordinary untreated paper stocks, whether coated or uncoated; and on practically any plastic packaging film or label stock; and the production of abrasion- and scratch-resistant images.

|

|

The Nanographic Printing process begins with the jetting of billions of droplets. However the droplets are not ejected directly onto the substrate as they are in the traditional inkjet process. Instead, they are ejected onto a blanket from ink ejectors that are mounted on print bars, onto a blanket positioned 1-2 mm away.

|

|

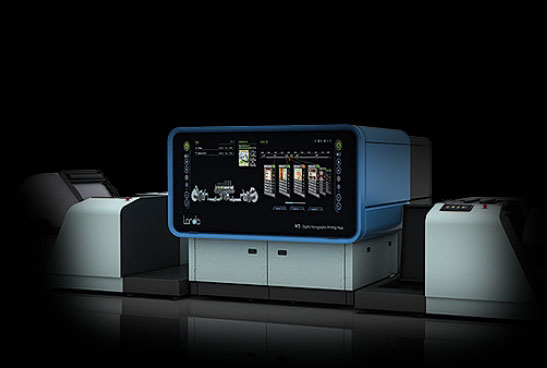

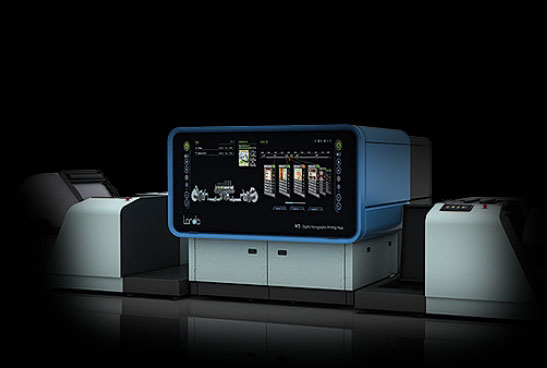

Each print bar prints a specific color. Landa Nanographic Printing Presses are equipped with eight print bars (Fig. 2) and are therefore capable of printing up to eight different colors simultaneously. Furthermore, the eight print bars can be employed for CMYK, spot or specialty colors such as white.

|

|

The eight print bar configuration allows having two color bars for each color, which in combination with doubling the paper handling system speed, allows doubling the productivity while maintaining the print quality.

|

|

The ink drop ejection onto the blanket is precisely timed to obtain very high accuracy between print separations and achieve high color plane registration.

|

|

| Landa W5 nanographic Printing Press.

|

|

For more information on this technology, there is a free White Paper – "The Nanographic Printing™ Process" – available for download on the Landa website here:

www.landanano.com/white-paper

|

|

Topics covered in the white paper include:

|

|

The characteristics and limitations of current digital printing technologies

The unique properties acquired by materials when reduced to the size of nanoparticles

A description of Landa NanoInk and the Nanographic Printing process

The special characteristics of dots printed with Landa NanoInk

The transfer of the printed image to any substrate

The white paper also explains how the Nanographic Printing process can yield the lowest cost-per-page of all digital printing technologies.

|