| Jul 30, 2013 |

Stabilisation of microdroplets using ink jet process

|

|

(Nanowerk News) Progress means that many things that are used in everyday life are becoming more manageable, practical and generally smaller. This also applies to biological and chemical experiments. To save material and resources, scientists are trying to reduce their experiments to increasingly smaller sizes and scales. But micrometre-sized droplets evaporate very quickly, making the smooth handling of a micro experiment difficult.

|

|

Patrick Galliker and Julian Schneider from the Laboratory of Thermodynamics in Emerging Technologies show how such tiny droplets can be controlled and stabilised ("Open-atmosphere sustenance of highly volatile attoliter-size droplets on surfaces").

|

|

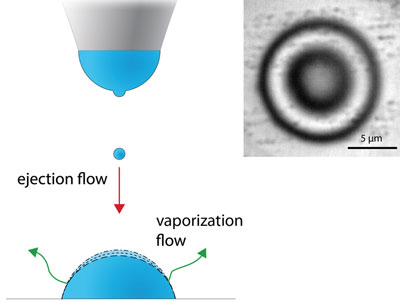

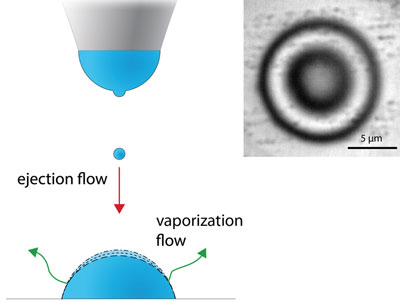

| A specifically designed inkjet print-head (left) allows stabilization of micrometer-sized droplets (right, from above).

|

|

For this purpose, they make use of a process that they developed for the 3D printing of nano electronic parts. Using a specially manufactured ink jet print head, the researchers produce nanometre-sized droplets of liquid, which may contain chemicals or biomolecules, for example. These droplets are placed at precise locations on a surface and eventually create a larger droplet of accumulated liquid that can be used as a nano or micro reactor for chemical or biological processes.

|

|

The large droplet is kept stable by constant supply of liquid that counteracts evaporation. The droplets that the researchers add to the large droplet for this purpose contain less than an attolitre of liquid, i.e. sextillionths of a litre. Furthermore, they can control the concentration of a substance in the droplet: by enlarging the total volume of the droplet, they reduce the concentration of a solute. Vice versa, they can increase the concentration by adding more of one chemical to the existing droplet or by allowing the droplet to partly evaporate.

|

|

Such precise control over the size and composition of microdroplets has been difficult to date. Until now, researchers have used chips with micro channels to mix tiny amounts of liquid, chemical substances and biomolecules. However, these chips must be specifically built for every experiment. Furthermore, scientists add an immiscible layer of oil to these chips, so that the aqueous solution in which the intended reactions take place does not evaporate.

|

|

The new ink jet process offers more flexibility and more precise control over the composition of reaction mixtures on the nanometre scale. “The great thing about our method is that it can be used for two completely different applications,” says Galliker. “In electrotechnology to print tiny electronic parts and in the biosciences to control micro experiments.”

|