| Mar 25, 2014 |

New electronic component paves the way for future flexible gadgets

|

|

(Nanowerk News) Research Fellow Dr Radu Sporea, Professor Ravi Silva and Professor John Shannon from Surrey’s Advanced Technology Institute (ATI), together with scientists from Philips Research, have shown how an electronic component, called a source-gated transistor (SGT), can improve the reliability of future digital circuits used within flexible gadgets.

|

|

The group’s findings have been communicated within their paper ‘Source-gated transistors for order-of-magnitude performance improvements in thin-film digital circuits’, which has been published by Nature’s Scientific Reports.

|

|

|

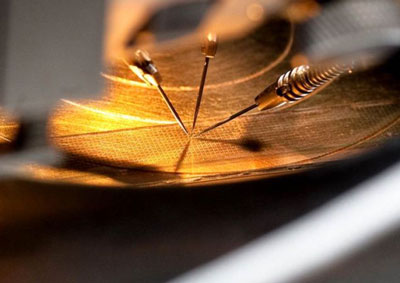

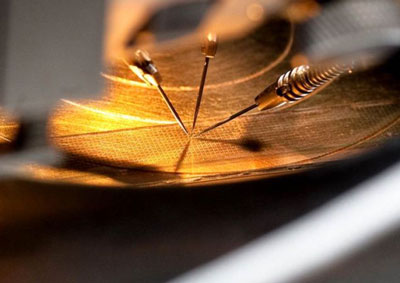

Existing transistors act as electronic switches, by changing the amount of current that flows through a semiconductor material by controlling the bias voltage across the channel region. SGTs, invented by the University of Surrey, instead exploit physical effects such as Schottky barriers at the metal-semiconductor contact, to control the electric current just as it enters the semiconductor channel from the circuit’s metals. This process relieves the semiconductor from some of its current-controlling duties, which benefits both device and circuit operation.

|

|

The team have shown that SGTs decrease the odds of circuit malfunction, improve energy efficiency and keep fabrication costs to a minimum. Despite a small penalty in operating speeds, digital circuits made with SGTs are less liable to computational error, even when they are used in environments with strong electromagnetic disturbance or unreliable power supply. These impressive properties make SGTs ideal for next-generation electronic gadgets, which are likely to be made on flexible plastic or even clothing, with ultra-low-cost manufacturing processes.

|

|

Dr Sporea elaborates, “The impact of our research is far-reaching and has many potential applications, from complex bendable consumer electronics to ubiquitous smart technology platforms. Thin-film digital circuits made up of SGTs might be used, for example, as ultra-low cost wireless tags embedded in packaging, which would let you check out in an instant, without stopping to unload your trolley. This idea has been proposed for a while, but with this technology we could now make realistically inexpensive yet reliable tags, with the gratifying prospect of abolishing checkout queues.”

|

|

Professor Ravi Silva, Director of the ATI and a co-author of the work, says, “This work is a classic example of academia working closely with industry for over two decades to perfect the operations of a completely revolutionary device concept suitable for large area electronics. This device architecture can be applied to traditional disordered materials such as poly-silicon and organic materials, and possibly state-of-the-art graphene thin films, a material that is now backed by the EU Flagship programme of €1Bn over the next ten years. The ATI have a team of excellent researchers working closely with industry on next generation technologies that will impact all of us.”

|