| Posted: Sep 26, 2011 | |

Mass-printed polymer/fullerene solar cells on paper |

|

| (Nanowerk Spotlight) Despites huge research funding for photovoltaics, contribution of solar cells to energy market is still negligible. The major obstacle is high production cost of silicon solar cells: current solar cell market is dominated by silicon technology. Bulky and rigid silicon solar cell with a power conversion efficiency above 10% and a lifetime of 25 years have become the benchmark in photovoltaic industry. However, there are plenty of scopes for disposable and inexpensive solar cells with a moderate efficiency and a shorter lifetime, which can be compared with plant leaves with a typical efficiency of 3-7% and a lifetime less than a year. Our research was motivated to produce cheap and disposable solar cells with a moderate power conversion efficiency. | |

| Organic photovoltaics have potentials to substantially lower the cost of solar cells. The added advantage of organic photovoltaics is that they can easily be disposed, if appropriate materials are selected. One of the best organic photovoltaics is bulk hetrojunction of polymer/fullerene, which was reported for the first time in 1992 (see: "Photoinduced Electron Transfer from a Conducting Polymer to Buckminsterfullerene"). | |

| Since then extensive works have been done to increase their efficiency and significant amount of works are ongoing to improve their stability. But no significant work has been done to decrease the total material cost and to simplify the manufacturing process. Expensive indium-tin-oxide is still an integral part of organic photovoltaics. Deposition of indium-tin-oxide on flexible substrates still involves expensive vacuum processes. Recently, we have developed a simple approach to print polymer/fullerene solar cells on paper substrates. | |

| The research article is published in the September 14, 2011 online edition of Advanced Energy Materials ("Printed Paper Photovoltaic Cells"). Our solar cell is free from expensive indium-tin-oxide and does not employ any vacuum process. | |

|

|

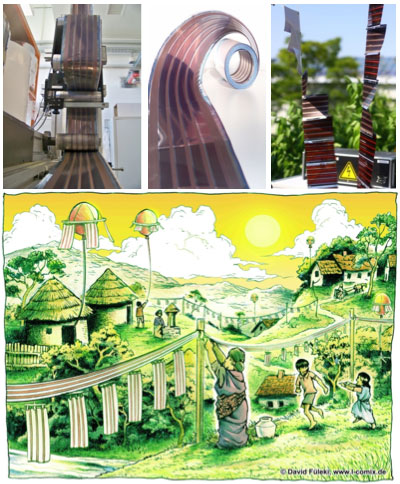

| Polymer/fullerene solar cells are printed on paper substrate by the combination of gravure and flexographic printing techniques in ambient conditions. The process does not require any vacuum steps. A Paper-roll of printed solar cells is shown. Solar modules can be made by any unskilled person just by cutting the rolls into desired sizes and connecting them with the help of commercial snap fasteners. The vision is to produce cheap, disposable and use-and-throw solar cells anywehere in the world, which can be printed by nearby printers or copy-shops and do not require any technical skill. (Images: Prof. Arved Hübler and his group, Institute for Print and Media Technology, Chemnitz University of Technology, Germany) | |

| We used only three roll-to-roll printing steps, under normal room conditions, to print the complete solar cells. Naturally oxidized zinc film, printed by transfer printing on paper, acts as cathode. Photoactive layer is a bulk hetrojunction of polymer/fullerene, printed by gravure printing. Poly(3,4-ethylenedioxythiophene) poly(styrenesulfonate) (PEDOT:PSS), printed by flexographic printing, acts as transparent anode. Gravure and flexographic printing processes are well-established techniques in conventional printing with a resolution of down to 10 µm, high printing speeds (up to 15 m/s) and low wastage of ink. | |

| We can do free patterning of all the three functional layers by gravure and flexographic printing techniques. The advantage of free patterning of all these layers is that it eliminates any extra process required to interconnect solar cells into a solar module. Our group has long expertise in tradition printing technology and has already demonstrated more complex device structures for integrated electronic circuitry in 2007 (see: "Ring oscillator fabricated completely by means of mass-printing technologies"). | |

| Despite the high surface roughness of paper substrate, our printed paper photovoltaic cells show a power conversion efficiency of 1.3% under an illumination level of 60 mW/cm2 and yield open-circuit voltage and short-circuit current density of 0.59 V and 3.6 mA/cm2, respectively. This is one of the first steps in the direction of 'paper energy'. Recently, researchers have started talking about paper electronics (see: "Paper Electronics") and our paper photovoltaics could be easily used to drive these paper-based electronic components. Our paper photovoltaics could also be applied as a basic power source for futuristic printed electronic devices e.g. smart packages. | |

| The major component (by volume) of our solar cells is paper (>90%). A paper substrate has several advantages, since it is inexpensive, eco-friendly, bio-degradable, easily recyclable, mechanically flexible and compatible with well-established printing processes. Rest of the materials are glue, zinc-foil, ZnO, fullerene and polymers. Our solar cell is free from any harmful materials and can be recycled together with aluminum-coated food packages by the existing recycling systems. | |

| Still there are plenty of rooms for further improvements in our solar cells. Efficiency of our solar cells can be improved by optimizing material properties, layer thicknesses and printing process parameters. ZnO layer thickness, surface roughness, crystallinity and charge carrier concentration can substantially influence the performance of our solar cells. Therefore, a systematic study is required in that direction to enhance the power conversion efficiency. | |

| Our technology can lead to the mass-production of paper photovoltaics by local newspaper or magazine printers anywhere in the world. The three steps printing approach for inexpensive solar cells, has potential to transform the sophisticated solar cells production unit into a compact printer. The visionary compact printer for solar cells can be compared to a copy-machine which can be easily installed in any part of the world with a small investment. The vision is to make green energy easily and cheaply available to masses. Our printed paper photovoltaics can bring new concept of use-and-throw solar cells. | |

| By Dr.-Ing. Moazzam Ali, Institute for Print and Mediatechnology, University of Technology Chemnitz | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|