| Posted: May 11, 2018 | |

A full gamut of colors in all-dielectric, cheap, and large-scale artificial butterfly wings |

|

| (Nanowerk Spotlight) Most natural and artificial colors are formed due to selective light absorption by pigments or dyes. An alternative mechanism of color formation is observed in the bright colors of some butterflies, beetles, and beautiful stained glass windows of old churches. This kind of color forms as a result of the frequency-selective light scattering by micro- and nano-scale structure inside the material, and is commonly known as the ‘structural color’. | |

| Structural colors are robust and can be reversibly changed by temperature variations, material deformations, and material saturation with gases or liquids. Materials with engineered colorimetric signatures detectable by the naked eye are in high demand for optical sensing and security applications. However, most approaches to making artificial structural colors rely on low-throughput fabrication techniques, use expensive noble metal materials, and are limited to microscopic footprints. | |

|

|

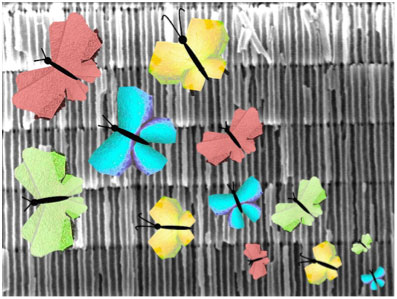

| Figure 1. Intricate meso-scale internal structure of the all-dielectric porous metamaterials enables structural color formation akin to that displayed by colorful butterfly wings. (Image: MIT) | |

| To address these limitations, an international team of researchers from Massachusetts Institute of Technology and the Institute of Micro and Nanotechnology in Madrid demonstrated high-throughput fabrication of all-dielectric mesoporous materials with macroscopic footprints and colorimetric signatures spanning the whole gamut of visible colors (Fig. 1). | |

| They reported their findings in the recent ACS Photonics article "Engineering a Full Gamut of Structural Colors in All-Dielectric Mesoporous Network Metamaterials". | |

| Inspired by the butterfly wing coloration, the researchers completely avoided the use of noble metals, and instead realized structural colors in cheap and abundant dielectric materials, which are completely transparent in the bulk form. | |

| The team led by Marisol Martin-Gonzales at IMN and Svetlana V. Boriskina at MIT engineered and fabricated mesoporous network metamaterials via the electro-deposition method by selectively etching through anodic aluminum oxide (alumina) to create ordered three-dimensional internal structure. Low refractive index of alumina limits the range of achievable structural colors, as porous alumina materials with two-dimensional order typically exhibit only one reflection band. | |

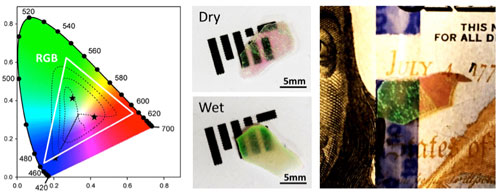

| In contrast, either one or multiple reflection bands form colorimetric response of the new family of 3D porous alumina structures. This allows for tuning of their structural color within the full range accessible by standard red, green, blue (RGB) display technologies (Fig. 2, left). | |

|

|

| Figure 2. (left) The structural colors of the fabricated porous samples (dotted black line) span the full gamut of colors accessible by standard RGB color display technologies (white triangle). (center) Environmental changes induce color change detectable by the naked eye. (right) Color changes of metamaterials on different substrates can yield applications in security and anti-counterfeiting. (Image: MIT) (click on image to enlarge) | |

| The researchers demonstrated structural color sensitivity to environmental changes, which did not require expensive microscopes to be observed, and instead was easily detectable by the naked eye (Fig. 2 center). The nanoporous structure of the 3D samples enables fast and easy penetration of liquids and gases throughout the sample volume and the corresponding change in their perceived color. | |

| Furthermore, since alumina is transparent across the whole visible range, the mesoporous samples exhibited striking color variations if placed on different substrates (Fig. 2 right). This feature makes the new structures potentially useful for security, anti-counterfeiting, camouflage detection, and food safety applications, as they can help to discriminate metamer materials exhibiting colors indistinguishable by the naked eye. | |

| The alumina structures can be further used as templates in cheap and high-throughput fabrication of inverse-structure metamaterials made of plastics, metals and semiconductors. This can expand their application range and help achieve sensing selectivity. | |

|

Provided by MIT as a Nanowerk exclusive

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|