| Jan 18, 2019 | |

Nanowire meshes to improve electrochemical devices |

|

| (Nanowerk Spotlight) Porous metals with high surface area are widely used as structural current collectors in numerous applications such as catalysis, filtration, sensors, fuel cells, batteries, supercapacitors, or electrolyzers. Nanostructuring of metallic current collectors has disruptive potential in increasing the power and reducing the size of these devices. | |

| Still, an optimal current collector needs to be mechanically durable and should exhibit a balanced combination of high surface area and a high porosity, distributed over sufficiently large and interconnected pores, whose optimal size depends on the particular application. | |

| Such non-trivial combination of properties enables fast transport of electroactive species to the extended surfaces of a current collector, increasing e.g. the charging speed of a battery or sensitivity of a sensor. | |

| Currently, however, even the state-of-the-art porous metals show a trade-off between their individual textural properties – porosity and surface area – and mechanical stability, which to a big extent is a consequence of the random microstructure of these materials. | |

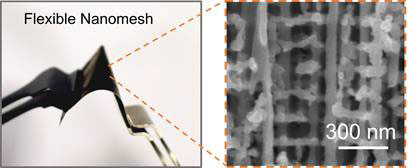

| In our recent work, published in ACS Applied Materials & Interfaces ("Combining High Porosity with High Surface Area in Flexible Interconnected Nanowire Meshes for Hydrogen Generation and Beyond"), we describe novel flexible networks of interconnected nickel nanowires (referred to as nanomesh). Thanks to its ordered microstructure, the material can uniquely combine high porosity of cellular metal foams with high surface area of state-of-the-art nanoporous dealloyed metals, which allowed it to surpass the electrochemical performance of up to 300-thicker commercial electrodes. | |

|

|

| Left: Photograph of a flexible nanomesh sheet. Right: SEM image of the cross-section of nanomesh made from AAO templates formed at 85 V. (Image: KU Leuven and imec) | |

| Working at the boundary between research and industry at imec in Belgium, our group has been looking for candidate nanostructured current collectors which could be suitable for novel high-power electrochemical devices developed in our team. | |

| Upon screening different candidate materials, we focused on interconnected nickel nanowires made from 3D-porous anodic aluminum oxide (AAO) templates. | |

| Although we noticed that the textural properties of such 3D-nanowire networks have never been quantified, they intuitively exhibit very large surface area, with the additional potential for large-scale and cheap electrochemical fabrication. The last two factors are also crucial for bringing materials from the laboratory to the market. | |

| However, we found that the previous nanowire networks consisted of thick and relatively densely-packed nanowires, which in theory results in low porosity of the current collector. | |

| Thus, supported by computer modeling of the network geometry, we rationally re-designed both the structure and the fabrication method of the nanowire frameworks to ensure high porosity of the end material. | |

| We also dedicated large effort to developing an experimental method for accurate determination of the surface area and porosity of such nanostructured metals (these results have now been submitted for a separate publication). | |

| As a result, we obtained macroporous nickel nanowire meshes, which are the first to combine high porosity of cellular metal foams (over 75%), substantial amount of macropores (larger than 50 nm) and a very large surface area of nanoporous dealloyed metals (above 20 m2 in each cubic centimeter). | |

| To visualize this, if a nanomesh sample filled a volume of a small can of soda, it would remain 75% empty, at the same time containing a surface area equal to the size of a football field! | |

| We found that such combination of structural properties is unique with respect to over 70 examples of different porous metals reported in the literature, including the state-of-the-art nanostructured materials such as nanoporous metals or metal aerogels. | |

| By simple modifications of AAO templates we also show how the textural properties of the nanomesh can be further optimized for some of its many possible device applications. | |

| Furthermore, by introducing selective metal etching to the manufacturing technique, we made free-standing nanomesh foils with excellent mechanical flexibility and, remarkably, no degradation upon extensive flexing. This marks an important improvement over the nanoporous dealloyed metals or metal aerogels, whose large brittleness and problematic handling limits their practical application in devices. | |

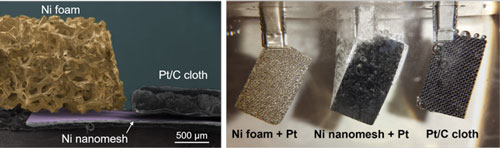

| Finally, to effectively demonstrate the advantages of the properties of the nanomesh, we applied it as a cathode in electrolytic hydrogen generation. Thanks to its very high surface area, the few micron thick nanomesh delivered more than 10-times higher H2 generation current compared to a millimeter-thick commercial nickel foam. | |

|

|

| Left: Colored SEM image of a 1.5 mm thick Ni foam (yellow) and a 0.41 mm thick Pt/C cloth (black), laying on a 4.8 µm thick Ni nanomesh (violet). Right: Photograph of the materials during hydrogen evolution in 1 M KOH at 0.5 V vs. RHE (Image: KU Leuven and imec) (click on image to enlarge) | |

| Also, thanks to the high porosity, large pores and good electrical conductivity of the nanowire network, the nanomesh doped with small amount of platinum surpassed the performance of a commercial microporous platinum/carbon cloth, which is typically considered as a reference material with the highest activity towards hydrogen generation. | |

| Still, due to the progressing passivation of nanostructured nickel surfaces in alkaline and cathodic environment, maintaining high activity of the nanomesh during prolonged hydrogen generation remains a challenge, which could be addressed in the future studies. | |

| Nevertheless, our results show that the unique combination of properties within the nanomesh current collector can lead to significantly increased performance of an electrode, with simultaneous reduction (in our example, up to 300 times) of its size. | |

| In conclusion, by re-designing the interconnected nanowire networks we fabricated novel nanostructured current collectors, which are the first to combine very high surface area, high porosity, substantially large pores and mechanical flexibility. | |

| Importantly, these features can be easily optimized and engineered toward any particular application. Since the nanomesh is essentially a universal, free-standing and flexible structural current collector, it promises simultaneous miniaturization, improvement of performance and mechanical flexibility of various electrochemical devices, such as batteries, fuel cells or sensors, extending to even broader applications, such as electrofiltration or solar water heaters. | |

|

Provided by KU Leuven and imec as a Nanowerk exclusive

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|