| May 21, 2019 | |

Improving the performance of carbon nanotube fibers |

|

| (Nanowerk Spotlight) Carbon nanotube (CNT) fiber is an important one-dimensional macroscopic material. The directional assembly of CNTs can help the fiber realize high mechanical, high electrical and high thermal performance. | |

| Unlike in structures with dispersed carbon nanotubes, the CNTs in the fibers are ordered and dense. This facilitates the conduction of heat flow along the direction of the fiber arrangement, thereby achieving efficient heat conduction. However, gaps between the carbon nanotube bundles limit the fibers'performance. | |

| By introducing thermosetting polymer between the carbon nanotube fibers, the cured polymer can overcome the weak van der Waals interaction between the CNTs and further improve the fiber thermal transport. This is advantageous for the application of carbon nanotube materials in the field of micro- and nanoelectronics. | |

| Recently, researchers led by Associate Professor Lin Qiu (Professor Yanhui Feng’s research group) from the University of Science and Technology Beijing and Professor Xiaohua Zhang from Suzhou Institute of Nano-Tech and Nano-Bionics (Chinese Academy of Sciences) controlled the fiber-polymer composite structure, and they achieved an effective improvement in thermal conductivity and mechanical properties of CNT fibers. | |

| This report can help researchers to achieve efficient performance control of carbon nanotube fibers, and the relevant research has been published in Carbon ("Electro curing of oriented bismaleimide between aligned carbon nanotubes for high mechanical and thermal performances"). | |

|

|

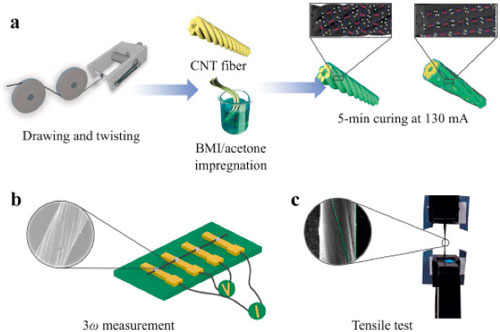

| Preparation of the CNT fibers. Stretching and spinning the carbon nanotubes prepared by vapor deposition method into CNT fibers. Then impregnating the fibers with bismaleimide (BMI) resin and curing the impregnated fiber with electricity to obtain the oriented composite fiber structure. (© 2019 Elsevier Ltd. All rights reserved) (click on image to enlarge) | |

| In this study, the researchers introduced bismaleimide (BMI) resin between carbon nanotube fibers, and then employed an electrocuring method to make the polymer resin form an oriented structure on the surface of the fibers. | |

| Polarization Raman was used to characterize the structure of the resin. By using the third harmonic test method, which has been proved suitable for one-dimensional nanomaterials, it is shown that electrocuring increased the thermal conductivity of the fiber by more than five times (from 30 to 177 W/m·K). | |

| Qiu et al. also considered the effect of radiation caused by their length on the apparent thermal conductivity of CNT fibers. They semi-quantitatively analyzed the thermal radiation contribution from the bundles area on the non-solid fiber surface with the increase of length. Different from carbon fiber with solid structure, the CNT fiber is composed of carbon nanotube bundles. The bundles near the surface have an impact on the apparent thermal conductivity of the fiber, so the apparent thermal conductivity will show a quadratic growth relationship with the change of length. | |

| In addition to the thermal properties, the mechanical and electrical properties of CNT fibers are also determined by the properties between the tubes. In this study, the researchers found that the fibers with high thermal conductivity after electrocuring also had high Young's modulus, up to a maximum of 43.1GPa. | |

| The dense fiber structure after curing is also conducive to enhancing the electron jump between CNTS and improved electron transport. | |

|

Provided by University of Science and Technology Beijing as a Nanowerk exclusive

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|