| Jan 21, 2020 | |

Smart soft robotic grippers enabled by self-powered tribo-skins |

|

| (Nanowerk Spotlight) Grippers or end effectors are an essential tool integrated with robotic arms for implementing grasping and manipulating functions in a variety of tasks, ranging from picking up and holding objects, to digging and sorting, to locomotion and scratching. | |

| Although traditional rigid grippers are able to operate accurately and provide a wide range of forces in different kinds of tasks, they face challenges in achieving high flexibility and dexterity like human hands, safe interactions with humans and environments, and grasping and manipulating soft or fragile objects. | |

| Spartan engineers from Michigan State University (MSU) have developed a new kind of smart soft actuator, based on the triboelectric nanogenerator (TENG), to fabricate intelligent grippers for robotics, aiming at potential applications in the areas of agriculture, engineering and healthcare and beyond. | |

| The prototype is reported in the journal Advanced Materials Technologies ("Smart Soft Actuators and Grippers Enabled by Self-Powered Tribo-Skins") in a paper by Dr. Changyong Cao, Assistant Professor at MSU School of Packaging, Mechanical Engineering (ME) and Electrical and Computer Engineering (ECE) Departments (by courtesy), with graduate student Shoue Chen, Dr. Yaokun Pang, Prof. Hongyan Yuan (SUSTech), and Prof. Xiaobo Tan from ECE Department. | |

|

|

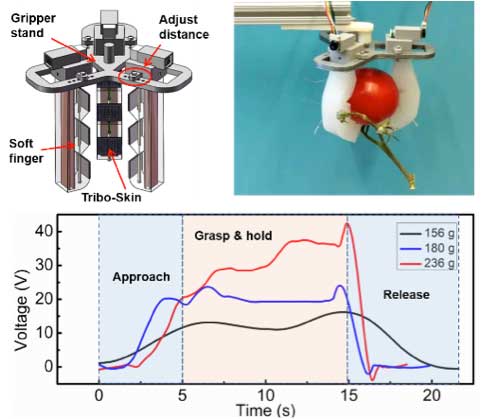

| The proposed finger-like soft actuator is designed based on a cable-driven mechanism by DC motors, that is capable of fast response and accurate control. The soft actuator is designed to have three segments of elastomers separated by two triangular cuts to facilitate bending and conformal contact with target objects of complex geometries. | |

| Two types of compliant TENG sensors are integrated into the soft actuator: rubber-based tribo-skin patches (single-electrode mode) attached to the surfaces of phalanges to measure contact pressure, and an inner TENG comprised of two strips (contact-separation mode) located on the backside of the finger to detect bending degrees. | |

| The tribo-skin patches are patterned with a micro-pyramid structure to improve their sensing and harvesting performance. Grippers assembled with three fingers has been demonstrated for grasping, sensing and energy-harvesting performance evaluation. | |

| “Currently, most soft grippers are based on the pneumatic pressure actuation which generally requires additional equipment for supplying air or hydraulic pressure, hindering the dexterity and miniaturization of the whole system. Other methods like grippers based on soft active materials like shape memory polymers are suffering the slow response and limited force/strain.” said Dr. Cao, the PI of the MSU’s Laboratory of Soft Machines and Electronics (SME), “Cable-driven approach could overcome the limits and achieve an accurate but simple control in manipulations.” | |

| The researchers utilized the TENG technology and invented a noel sensor of simple structure to detect the bending angle, grasping force/pressure and to generate electricity for powering other kinds of sensors. They have investigated the influence of the key factors for the sensing and energy harvesting, and finally demonstrated its potential applications in grasping different geometry objects and harvesting tree fruits and vegetables in agriculture. | |

| “There are still some challenges to be solved for deploying this technology in field testing and large-scale applications.” Said Dr. Xiaobo Tan, the MSU Foundation Professor at ECE department, “With further effort in manufacturing and optimization, I believe that the smart soft gripper will be able to be used for agriculture harvesting, automation packaging, elderly care and beyond for safer and intelligent human-robotics interactions in the future.” | |

|

Provided by Michigan State University as a Nanowerk exclusive

|

|

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|