| Aug 11, 2021 | |

A ground-breaking modeling toolkit to predict current of new type of memory |

|

| (Nanowerk Spotlight) Resistive-switching memory (RSM) is an emerging candidate for next-generation memory and computing devices, such as storage-class memory devices, multilevel memories and as a synapse in neuromorphic computing. | |

| RSM devices have gained significant attention due to their simple metal-insulator-metal (MIM) structure, which composes a dielectric material sandwiched between the top electrode (TE) and bottom electrode (BE). | |

| RSM operation is based on resistive switching, which is generally known as set process if the device switches from high resistance state (HRS) to low resistance state (LRS) and reset process if the device switches from LRS to HRS. | |

| Such processes depend on the amplitude and polarity of applied voltage in the unipolar and bipolar-switching modes, respectively. Applying a voltage between the TE and BE leads to the formation of nanoscale conduction filament (CF) in set process and the rupture of CF in reset process. | |

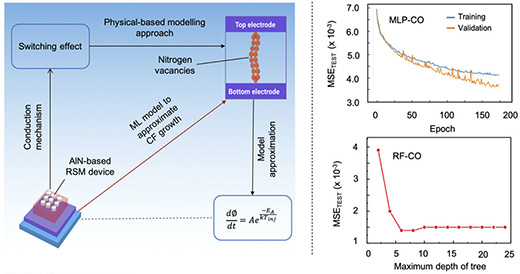

| The formation of CF in RSM devices is typically based on electrochemical metallization (ECM) effect, valence-change memory (VCM) effect, thermochemical memory (TCM) effect and other effects. Aluminum-nitride-based RSM device exhibits bipolar switching. The growth of CF is governed by VCM effect and CF is formed by nitrogen-vacancies. | |

| Traditional physical-based models based on CF growth are generally used to model the RSM device characteristics. Conventional physical-based models consider various assumptions such as the shape, growth direction and temperature distribution of CF to describe the switching behaviour of RSM devices. | |

| However, the assumptions could also lead to less reliable, less accurate and too device-centric models to describe the switching behaviour. Therefore, it is essential to model CF growth of RSM devices using new methodologies to accurately model the switching behaviour. | |

| In this report (AIP Advances, "Modeling electrical conduction in resistive-switching memory through machine learning"), we present an alternative ML approach in which we avoid the need to solve traditional physical-based equations by directly learning the relationship between other-device-parameters to compute the CF-related compliance current (CC) value i.e., we establish a ML-CO model. | |

|

|

| Overview of the model for predicting the current of the new type of memory. (Image: SUTD) (click on image to enlarge) | |

| We show that this relationship can be learned via a data-driven approach and with excellent accuracy for many different samples to describe CF growth. Furthermore, we show that it can immediately be applied to real-device sampling by computing the CC value of RSM devices with just a few device parameters. | |

| Moreover, as we have already implemented the approach with common aluminum-nitride-based RSM devices and verified the developed ML models on SiOx and TiO2 RSM devices, this can now be performed on a much wider range of RSM devices. | |

| We have achieved three significant results in this work: | |

|

|

|

| By applying ML algorithms to learn the relationship between other-device-parameter values to compute the CC value, the proposed ML-CO model allows accurate prediction of CF growth to describe the switching behaviour. The data-driven ML approach can also be implemented and performed on a much wider range of RSM devices. | |

| Additionally, achieving an appropriate CC value in a dynamic manner using AI-engine plugin could pave the way for programmable memory applications, e.g., in-memory computing. And this work would be of significant interest to the research community, including material scientists, electronic engineers, device manufacturers and computer designers, as a tool for discovery of new RSM materials and rapid screening of nanomaterials suitable for RSM, which could drive RSM commercialization. | |

| Source: Provided by Singapore University of Technology and Design as a nanowerk exclusive | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|