| Dec 16, 2022 | |

New experimental setup achieves unprecedented accuracy in strain engineering of 2D materials |

|

| (Nanowerk Spotlight) A new motorized three-point-bending apparatus has been developed that is capable of automating strain engineering experiments on two-dimensional (2D) materials. The setup can be used to apply precise, uniform strain to 2D materials such as MoS2, allowing researchers to study the effects of strain on the electrical and optical properties of these materials. | |

| The system can also be used to study straintronic devices, devices whose output characteristics can be adjusted by means of applied strain. This automated system could help researchers studying strain engineering in many other 2D materials to acquire larger and more precise datasets. | |

| A team of researchers from the Instituto de Ciencia de Materiales de Madrid (part of the Spanish National Research Team) has developed an automatized experimental setup that allows for strain engineering experiments with two-dimensional materials with unprecedented accuracy and reproducibility (Advanced Materials Technologies, "An Automated System for Strain Engineering and Straintronics of 2D Materials"). | |

|

|

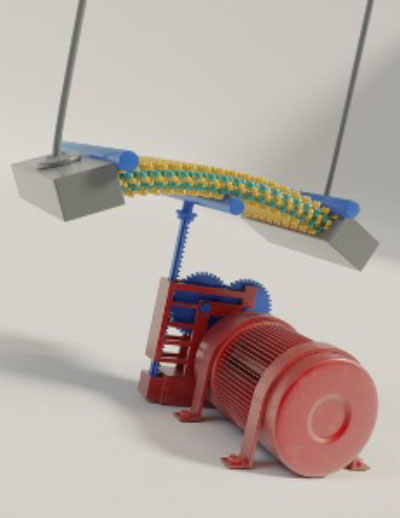

| Artistic impression of the motorized bending setup to perform precise and accurate strain engineering experiments on 2D materials and 2D-based optoelectronic devices. (Image: Enrique Sahagún, SCIXEL). | |

| The setup employs a motorized stage and three-point bending apparatus to control the applied strain on the materials, enabling very small displacements of as little as 20 nanometers. | |

| "Up to now, the experimental setups used in the literature relied on the use of manually actuated straining setups with a larger inherent inaccuracy," said Dr. Andres Castellanos-Gomez, lead author on the study. "Our motorized stage and three-point bending apparatus allows for much greater control and precision in applying strain to the materials, leading to more accurate and reproducible results." | |

| In addition to its high levels of accuracy and reproducibility, the experimental setup also allows for unattended experiments and the collection of larger datasets - up to 10-100 times more than previous manual approaches. This larger dataset will enable the observation of more subtle phenomena and improve our understanding of two-dimensional materials. | |

| The researchers also demonstrated the potential applications of their experimental setup by using it to develop a strain-tunable single-layer MoS2 photodetector. The device, which is fabricated onto a polycarbonate substrate, acts as an adaptable photodetector that can be controlled through the application of mechanical strain. | |

| "Our experimental setup has a lot of potential applications in the emerging field of straintronics, where devices can be controlled through the application of mechanical strain," said Dr. Castellanos-Gomez. "We're excited to see what new discoveries and innovations will come from our future experiments." | |

| Provided by Instituto de Ciencia de Materiales de Madrid | |

|

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com. |

|