| Posted: Jul 11, 2006 | |

Mass-producible replication of highly hydrophobic surfaces from plant leaves |

|

| (Nanowerk Spotlight) Superhydrophobic surfaces, such as lotus leaves, with micro/nano combined structures found in nature have attracted many researchers’ interest because of their importance in fundamental research and practical applications such as self cleaning, anti-fogging/snowing, drag reduction effect etc. In this regard, diverse methods have been proposed to produce such surfaces. These methods might be categorized as chemistry based processes and MEMS (MicroElectroMechanicalSystem) based processes. However, most of the reported methods in the literature generally require a cleanroom-based process or complex chemical processes and have some limitations in terms of mass-production capability and material selectivity. | |

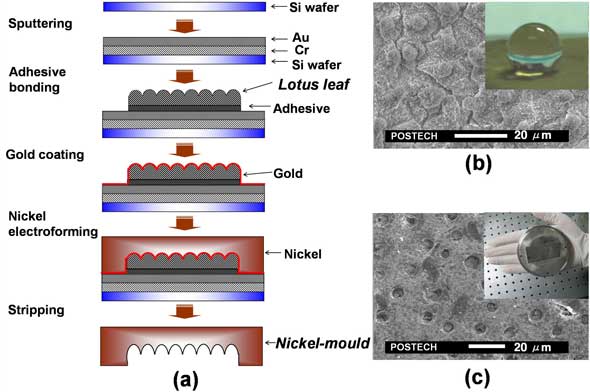

| In our recent work ("Mass-producible replication of highly hydrophobic surfaces from plant leaves"), we demonstrate a mass-production fabrication method for hydrophobic surfaces by simply replicating the plant leaf surfaces in two steps: the first step of nickel-mould making via electroforming and the second step of replication via UV-nanoimprint lithography (or injection molding and hot embossing). | |

| Through this work, the feasibility to make a nickel-mold directly patterned upon plant leaves was successfully confirmed and thus produced polymer replica from UV-NIL also showed quite successful replication quality in view of hydrophobicity and topographic similarity between the used plant leaves and their corresponding polymer replicas. | |

|

|

| (a) Schematic of nickel mould making process making use of nickel electroforming process; (b) Scanning electron micrograph (SEM) of the real lotus leaf and the inset is a water drop on it (contact angle = 168.0 ± 1.4°); (c) SEM of the nickel mould patterned upon lotus leaf and the inset is a real photograph of the mould. (Image: Seung-Mo Lee and Tai Hun Kwon, Pohang University of Science and Technology) | |

| We regard the detailed nickel mold making procedure of electroforming over the natural leaf surface employed in this work as a new mold making technique for a mold insert to be used in replicating positive replicas from nature directly. It may also be mentioned that the cost-effectiveness and mass production capability of the superhydrophobic surfaces can be maximized through the other manufacturing technologies such as injection molding, hot embossing and polymer casting using thermally curable polymer etc, since the nickel- mold fabricated in this work can also be utilized as a mold insert regardless of fabrication technologies. More importantly, above mentioned manufacturing technologies enable final replica products of various polymeric materials such as polystyrene (PS), poly(methyl methacrylate) (PMMA), polycarbonate (PC), cyclic olefin copolymer (COC), polydimethylsiloxane (PDMS) and so on. | |

| In view of the applications which can be achieved making use of our method, it may be mentioned that one can produce facing materials which have very low flow resistance, which is believed to be widely used in the field of aerospace and ship building engineering. And the facing materials could also be used as a type of tiles in the field of the building industry and kitchen utensils industry, which is expected to reveal self cleaning effects. | |

|

|

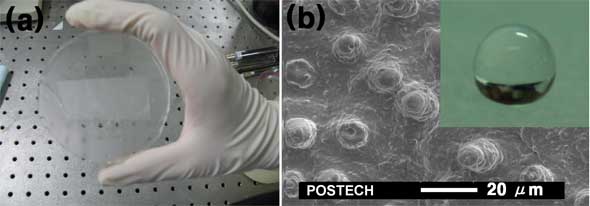

| (a) Photograph of superhydrophobic surface produced by polymer casting using PDMS; (b) SEM of the surface (a) and the inset is a water drop on it (contact angle = 163.3 ± 1.8°). (Image: Seung-Mo Lee, Pohang University of Science and Technology) | |

| In this work, we have proved the feasibility of the nickel mould making patterned upon hydrophobic plant leaf directly and have successfully fabricated the hydrophobic surfaces using the nickel mold as a mold insert of UV-nanoimprint lithography. Recently, using the nickel mold directly patterned upon lotus leaf, we have newly attempted other manufacturing technologies such as, polymer casting and injection moulding etc. In the case of polymer casting, we have successfully fabricated superhydrophobic surfaces almost similar to the lotus leaf and injection molding approach has been also carried out. | |

| By Seung-Mo Lee and Tai Hun Kwon, Pohang University of Science and Technology, Pohang, South Korea. |

Become a Spotlight guest author! Join our large and growing group of guest contributors. Have you just published a scientific paper or have other exciting developments to share with the nanotechnology community? Here is how to publish on nanowerk.com.