| Posted: December 15, 2008 |

11-megapixel micro-mirror array for high-end industrial applications |

|

(Nanowerk News) At

today's IEEE International Electron Devices Meeting, IMEC presented a

monolithically integrated 11-megapixel micro-mirror array for high-end

industrial applications -- a world's first both in terms of pixel density

and reliability. Each mirror in the array is 8µm x 8µm and can be

individually tilted by the high-speed integrated CMOS circuitry underneath

the array. This device fits in IMEC's CMORE initiative, which offers

cost-effective solutions for continued system scaling, not by shrinking

CMOS but by focusing on monolithic co-integration of heterogeneous

technology.

|

|

IMEC's 10cm” 11-megapixel mirror array has a pixel density that is almost

double that of comparable state-of-the-art micro-mirrors. And IMEC has

demonstrated that its mirrors show no creep and meet 10-to-the-12th-power

cycles mechanical lifetime. Integrated micro-mirror arrays such as this one, are

used in, for example, video projection or lithography mask writers.

|

|

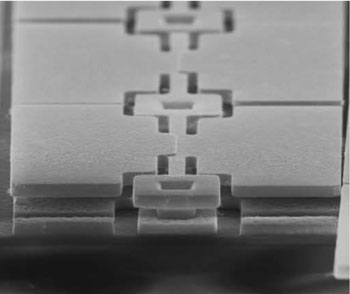

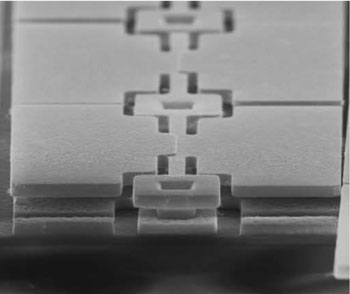

| Top view of individual mirrors and hinges (Image: IMEC)

|

|

IMEC fabricated the 8µm mirrors on top of foundry high-voltage 0.18µm CMOS

200mm wafers with 6 interconnect levels. The array was built using IMEC's

proprietary SiGe-based MEMS platform, meeting the mirror's mechanical

reliability requirements, device flatness, and compatibility with

high-speed CMOS. Poly-SiGe was chosen as structural material for the

mirrors, instead of Al. Poly-SiGe solves many of the reliability issues of

Al-based mirrors, and it is compatible with above CMOS processing, allowing

a smooth integration with the CMOS chip below.

|

|

IMEC's CMORE initiative offers cost-effective solutions for monolithic

co-integration of heterogeneous technologies. The services offered range

from development-on-demand, over prototyping, to low-volume production.

These services profit from the expertise in many research areas available

at IMEC. The CMORE solutions are implemented in IMEC's 200mm fab with

advanced packaging capabilities, such as 3D integration. The two process

platforms involved are a 0.13µm CMOS process and a versatile SiGe above-IC

MEMS process. On customer demand, the CMORE solution can be migrated to

IMEC's 300mm fab.

|

|

About IMEC

|

|

IMEC is a world-leading independent research center in nanoelectronics and

nanotechnology. IMEC vzw is headquartered in Leuven, Belgium, has a sister

company in the Netherlands, IMEC-NL, offices in the US, China and Taiwan,

and representatives in Japan. Its staff of more than 1650 people includes

more than 500 industrial residents and guest researchers. In 2007, its

revenue (P&L) was EUR 244.5 million.

|

|

IMEC's More Moore research aims at semiconductor scaling towards sub-32nm

nodes. With its More than Moore research, IMEC looks into technologies for

nomadic embedded systems, wireless autonomous transducer solutions,

biomedical electronics, photovoltaics, organic electronics and GaN power

electronics.

|

|

IMEC's research bridges the gap between fundamental research at

universities and technology development in industry. Its unique balance of

processing and system know-how, intellectual property portfolio,

state-of-the-art infrastructure and its strong network worldwide position

IMEC as a key partner for shaping technologies for future systems.

|

|

Further information on IMEC can be found at www.imec.be.

|