| Sep 10, 2013 |

New solution in human-machine cooperation

|

|

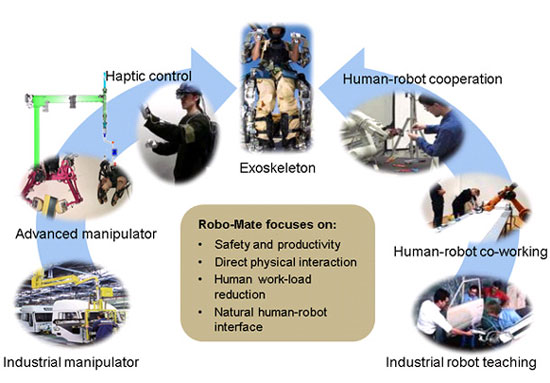

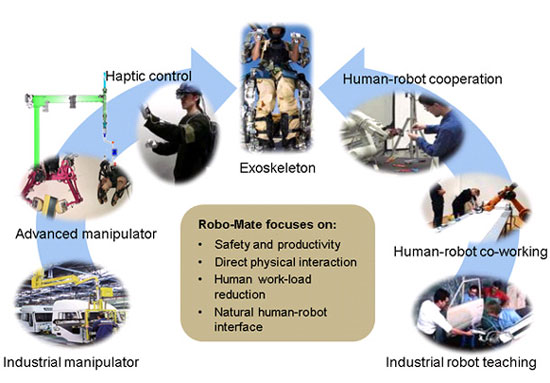

(Nanowerk News) The Fraunhofer Institute for Industrial Engineering IAO is partner in the Robo-Mate project, starting in September 2013. Together with 11 European partners this research project aims at designing a human-guided exoskeleton to improve work safety and enhance productivity in the industrial environment.

|

|

|

Various manual work tasks necessary to industrial manufacturing processes are difficult to automate – even today – due to their complexity. This is particularly the case in assembling and dismantling operations, such as those used in the automotive or food processing industries. This type of work, however, entails severe risks of injury. According to the Work Foundation Alliance (UK), as many as 44 million workers in the European Union are affected by work-place related musculoskeletal disorders (MSDs), representing a total annual cost of more than 240 billion Euros. To overcome these industrial and societal challenges, a new project, called Robo-Mate, has been designed.

|

|

Set to get underway in September 2013, the objective of the Robo-Mate project is to develop an intelligent, easy-to-manoeuvre, and wearable body exoskeleton for manual-handling work. The project comprises 12 partners from 7 European countries, including key players from industry and academia. The fundamental idea behind Robo-Mate is to enhance work conditions for load workers and facilitate repetitive lifting tasks, thereby reducing the incidence of work-place related injury and disease. As a consequence, productivity, flexibility and the quality of production will increase. Bringing this concept to fruition involves merging human-guided manipulators with computer-controlled industrial robots in order to create a human-guided and computer-supported exoskeleton for use in various industries.

|

|

The development includes modelling and simulating the exoskeleton in a virtual-factory environment at the Fraunhofer Institute for Industrial Engineering IAO. Demonstrations of the prototype will be held at INDRA SAS – a French company in the vehicle recycling sector – and COMPA S. A. – a Romanian automotive components manufacturer. The Centro Ricerche Fiat (CRF) will test the exoskeleton in their lab and on the Fiat shop floor.

|

|

Putting the Robo-Mate exoskeleton into service will engender practical and far-reaching impacts, including making the industrial work-site safer for skilled personnel, providing a means for workers to apply less physical effort, and facilitating higher-quality outputs resulting in industrial benefit.

|

|

Funded with €4.5 million by the 7th Framework Programme for Research and Technological Development of the European Union (FP7), the 3-year project will be led by Prof. Dr. Hans Wernher van de Venn, Zurich University of Applied Science (ZHAW), and managed by accelopment AG in Switzerland.

|