Magnetic Tunnel Junctions: Harnessing Quantum Tunneling for Spintronic Devices

What are Magnetic Tunnel Junctions?

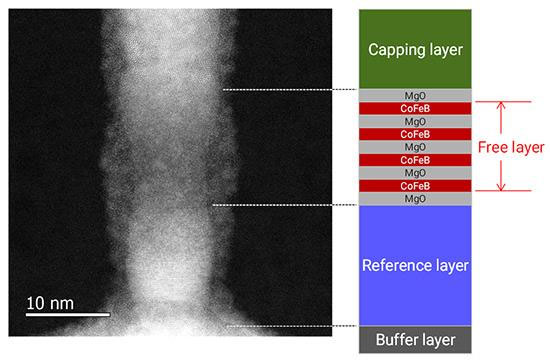

Magnetic tunnel junctions (MTJs) are nanoscale devices that consist of two ferromagnetic layers separated by a thin insulating tunnel barrier. The electrical resistance of an MTJ depends on the relative magnetization orientation of the ferromagnetic layers, a phenomenon known as tunneling magnetoresistance (TMR). MTJs are the fundamental building blocks of spintronic devices, which exploit the spin degree of freedom of electrons for information processing and storage.

Tunneling Magnetoresistance

The key phenomenon that enables the operation of MTJs is tunneling magnetoresistance. When the magnetization orientations of the two ferromagnetic layers are parallel, electrons with the same spin orientation can tunnel through the insulating barrier more easily, resulting in a low-resistance state. Conversely, when the magnetization orientations are antiparallel, the tunneling probability is reduced, leading to a high-resistance state. The TMR ratio, defined as the relative change in resistance between the parallel and antiparallel states, is a critical parameter that determines the performance of MTJ-based devices.

Spin-Transfer Torque

In addition to the TMR effect, MTJs also exhibit the spin-transfer torque (STT) phenomenon. When a spin-polarized current passes through an MTJ, it can exert a torque on the magnetization of the free ferromagnetic layer, causing it to switch orientation. STT-based switching enables the control of MTJ states using electrical currents, eliminating the need for external magnetic fields. STT-MTJs have become the basis for high-density, low-power, and fast non-volatile memory applications.

Materials and Fabrication

The performance of MTJs heavily relies on the choice of materials and the quality of the fabrication process. The ferromagnetic layers are typically made of alloys such as CoFeB or CoFe, while the tunnel barrier is usually composed of MgO or AlOx. The thickness and uniformity of the tunnel barrier are critical for achieving high TMR ratios and reliable device operation. Advanced deposition techniques, such as sputtering and molecular beam epitaxy, are employed to fabricate high-quality MTJ stacks with precise control over layer thicknesses and interfaces.

Applications of Magnetic Tunnel Junctions

Magnetic Random Access Memory (MRAM)

MTJs are the core elements of magnetic random access memory (MRAM), a type of non-volatile memory that combines the speed of SRAM, the density of DRAM, and the non-volatility of flash memory. In MRAM, each memory cell consists of an MTJ that stores a binary bit of information based on its resistance state. STT-MRAM offers fast read and write operations, low power consumption, and unlimited endurance, making it a promising candidate for next-generation memory technologies.

Magnetic Sensors

MTJs are also employed as highly sensitive magnetic sensors for various applications, including automotive, industrial, and biomedical sensing. The high TMR ratios of MTJs enable the detection of weak magnetic fields with high resolution. MTJ-based sensors offer advantages such as small size, low power consumption, and compatibility with CMOS manufacturing processes.

Hard Disk Drive Read Heads

MTJs have revolutionized the hard disk drive (HDD) industry by enabling ultra-sensitive read heads for high-density data storage. In HDD read heads, MTJs are used to detect the magnetic fields from the recorded bits on the magnetic media. The high TMR ratios of MTJs have allowed for the development of read heads with exceptional sensitivity and spatial resolution, enabling the continued scaling of HDD storage capacities.

Challenges and Future Perspectives

Despite the significant progress in MTJ technology, several challenges need to be addressed for their widespread adoption. One of the main challenges is the scalability of MTJs to sub-10 nm dimensions while maintaining high TMR ratios and low switching currents. The development of new materials, such as topological insulators and 2D materials, as well as innovative device architectures, such as perpendicular MTJs, are being explored to overcome these challenges.

Future research in MTJ technology will focus on enhancing the performance, reliability, and functionality of MTJ-based devices. The integration of MTJs with CMOS circuits and the development of hybrid spintronic-CMOS systems will enable the realization of energy-efficient and intelligent computing architectures. Additionally, the exploration of novel phenomena, such as spin-orbit torque and voltage-controlled magnetic anisotropy, will open up new avenues for spintronic device design and applications.

Further Reading

Orhanic Electronics, Magnetic tunnel junction based molecular spintronics devices exhibiting current suppression at room temperature

Wiley Encyclopedia of Electrical and Electronics Engineering, Magnetic Tunnel Junctions for Spintronics: Principles and Applications