Mechanosynthesis: Precision Molecular Manufacturing at the Nanoscale

What is Mechanosynthesis?

Mechanosynthesis is a proposed method of precisely controlling the assembly of atoms and molecules to build complex structures at the nanoscale. It involves the use of advanced molecular machines, known as assemblers or fabricators, to guide chemical reactions and manipulate individual atoms or molecular fragments. The goal of mechanosynthesis is to achieve atomically precise manufacturing, enabling the creation of materials and devices with unparalleled properties and performance.

Principles of Mechanosynthesis

The concept of mechanosynthesis is based on the principles of molecular nanotechnology and the idea of a molecular assembler, proposed by K. Eric Drexler in the 1980s. The key principles of mechanosynthesis include:

- Molecular Precision: Mechanosynthesis aims to achieve molecular precision by controlling the placement of individual atoms and molecules. This level of precision is essential for creating materials with well-defined structures and properties.

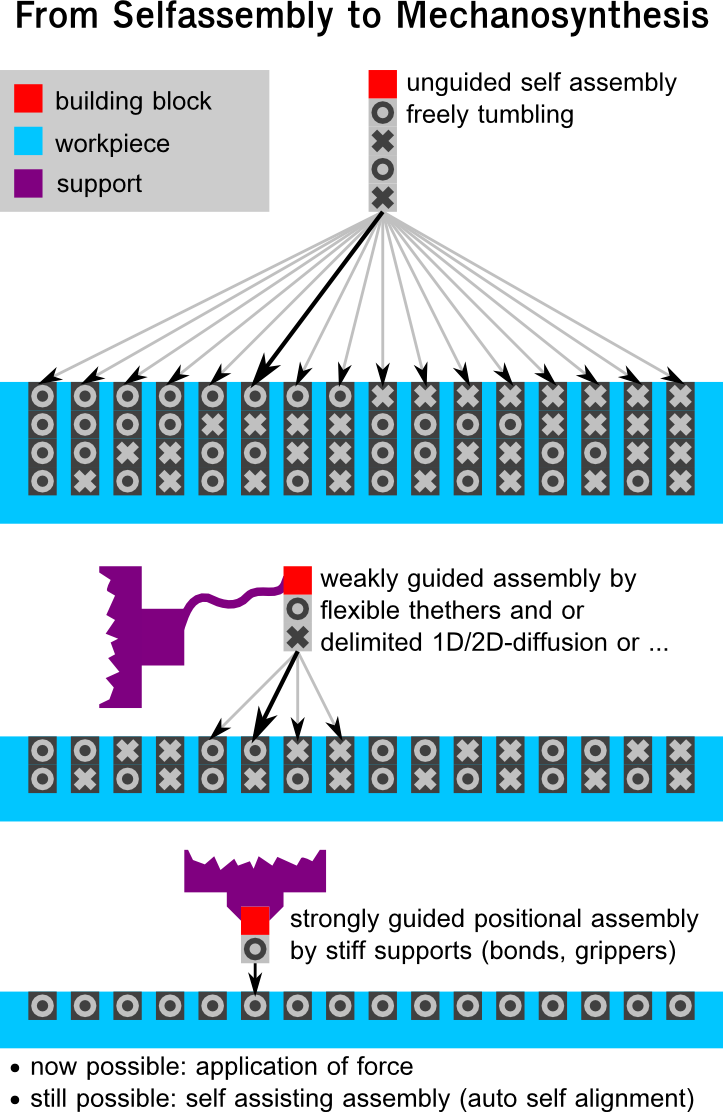

- Positional Assembly: In mechanosynthesis, molecular machines are used to pick and place atoms or molecular fragments in specific positions. This positional assembly enables the construction of complex nanostructures with atomic accuracy.

- Programmable Control: The molecular machines used in mechanosynthesis are envisioned to be programmable, allowing for the precise control of the assembly process. By programming the machines with specific instructions, it becomes possible to build a wide range of nanostructures and devices.

- Parallel Fabrication: Mechanosynthesis has the potential for parallel fabrication, where multiple molecular machines work simultaneously to build nanostructures. This parallel approach can significantly increase the speed and efficiency of the manufacturing process.

Challenges and Limitations

While mechanosynthesis holds great promise for atomically precise manufacturing, there are several challenges and limitations that need to be addressed:

- Molecular Machine Design: Designing and creating the molecular machines required for mechanosynthesis is a significant challenge. These machines need to be capable of precise manipulation at the atomic scale and must be able to operate reliably in a controlled environment.

- Energy and Information Transfer: Efficient transfer of energy and information to the molecular machines is crucial for their operation. Developing mechanisms for powering and controlling these machines at the nanoscale is an ongoing area of research.

- Scalability and Speed: Achieving large-scale production through mechanosynthesis remains a challenge. The speed and throughput of the assembly process need to be significantly improved to make mechanosynthesis viable for practical applications.

- Error Correction and Quality Control: Ensuring the accuracy and reliability of the assembly process is essential for producing high-quality nanostructures. Developing error correction mechanisms and quality control measures is necessary to mitigate defects and maintain the desired properties of the fabricated structures.

Potential Applications

If successfully developed and implemented, mechanosynthesis has the potential to revolutionize various fields and enable a wide range of applications:

- Advanced Materials: Mechanosynthesis could enable the creation of novel materials with precisely engineered properties, such as ultra-strong and lightweight composites, high-performance catalysts, and materials with programmable behavior.

- Nanotechnology and Nanorobotics: Mechanosynthesis could facilitate the development of sophisticated nanorobots and nanomachines capable of performing complex tasks at the nanoscale, such as targeted drug delivery, molecular sensing, and nanoscale manufacturing.

- Energy and Electronics: Atomically precise manufacturing through mechanosynthesis could lead to the development of highly efficient energy storage and conversion devices, as well as ultra-compact and high-performance electronic components.

- Biomedical Applications: Mechanosynthesis could enable the production of advanced biomaterials, drug delivery systems, and nanoscale medical devices for targeted therapies, regenerative medicine, and personalized healthcare.

Criticism and Skepticism

Despite the potential benefits and revolutionary implications of mechanosynthesis, the concept has faced criticism and skepticism from various scientific communities. Some of the main points of criticism include:

- Feasibility and Complexity: Critics argue that the level of precision and control required for mechanosynthesis may be beyond our current technological capabilities. The complexity of designing and manufacturing molecular machines that can reliably manipulate individual atoms and molecules is seen as a formidable challenge.

- Thermodynamic Constraints: Some scientists question the thermodynamic feasibility of mechanosynthesis, arguing that the energy requirements and heat dissipation at the nanoscale may pose significant obstacles to the practical implementation of the concept.

- Steric Hindrance and Molecular Interactions: Critics point out that the precise manipulation of atoms and molecules may be hindered by steric effects and complex molecular interactions. The ability to control and guide chemical reactions at the atomic scale is seen as a major hurdle.

- Lack of Experimental Validation: Mechanosynthesis remains largely theoretical, and there is a lack of experimental evidence demonstrating the feasibility of the proposed mechanisms. Skeptics emphasize the need for concrete experimental results to validate the concept and address the technical challenges.

- Competing Technologies: Some researchers argue that alternative approaches, such as self-assembly and biomimetic strategies, may be more promising for achieving precise control over nanoscale structures. These approaches are seen as potentially more feasible and scalable compared to mechanosynthesis.

While the criticism and skepticism surrounding mechanosynthesis highlight the significant challenges that need to be overcome, proponents argue that these challenges are not insurmountable. They emphasize the need for continued research and development to address the technical hurdles and provide experimental validation of the concept.

It is important to note that mechanosynthesis is still in the realm of theoretical and conceptual exploration, and it may take significant advances in our understanding of nanoscale phenomena and the development of novel technologies to bring it closer to practical realization. Open scientific discourse, rigorous experimentation, and collaborative efforts across disciplines will be crucial in assessing the feasibility and potential of mechanosynthesis in the years to come.

Further Reading

Chemical Science, Molecular assemblers: molecular machines performing chemical synthesis

K. Eric Drexler, Engines of Creation 2.0: The Coming Era of Nanotechnology (PDF)

ACS Central Science, Mechanochemistry: A Force of Synthesis